I will expand on DKNguyen answer, because to my knowledge also the two reasons are:

- reduce contact/bearing stresses (having a significant effect on thin finishes live galvanisation)

- change the joint tightening characteristics (see joint diagram).

reduce contact stresses on surfaces.

The basic idea is that since contact stress is defined as:

$$\sigma = \frac{F}{A}$$

Obviously the larger the area the less the stress. Also, like Nuclear Hoagie pointed out the area changes with a square law of the diameter.

UPDATE 2 - Calculation for M6 bolt (thanks to BenC)

*The question gathered enough interest for me to carry out a simple calculation on the M6 and M6 washer.

An M6 Bolt has the following characteristics:

figure 1: source (itafasteners.com)

- s=10 mm (See image above)

- diameter d = 6 mm

- M6 Hole Clearance $d_{M6,clear} = 6.6 mm$ (this is the typical diameter of a hole that will fit an M6).

The entire area of the bolt head (calculated as a hexagon area) is $86.6 mm^2$, but because of the clearance the effectively available area is about 52.4 $mm^2$.

On the other had the M6 washer has:

- $d_{in}$ = 6.4 mm (inner diameter)

- $d_{out}$ = 12 mm (outer diameter)

Therefore its effective contact area (on the side of the material) would be calculated as

$$A_{washer} = \frac\pi 4 (d_{out}^2- d_{M6,clear}^2)= \frac\pi 4 (12^2- 6.6^2)= 78.8 mm^2$$

So effectively the area with the washer is about 1.5 times greater than the area without the washer. Therefore, the contact stresses between the clamped material and the washer will be 1.5 times less that the clamped material and only the bolt.

Although with steel itself there is usually not much worry, the main problem with increased stresses on coatings of the material.

An interesting example I came across once: the forces on lap joint with a fastener were so great that the bearing stress of the zinc in the coating was exceeded. The result was that the coating would basically be removed. In the particular application the long term was that the anti-corrosion protection was removed.

Using wide washers solved the problem.

An additional benefit (related to the reduction of stresses) is that the washer is a replaceable item. So while tightening might damage the surface of the bolt and the clamp, the use of a washer might damage the contact surface between the bolt and the washer, but at the end of the day they can both be replaced.

Changing the tightening characteristics.

(this part is a bit more involved and I would suggest anyone interested to read more in a textbook like Shigley if they are interested).

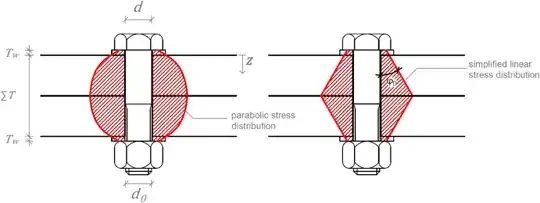

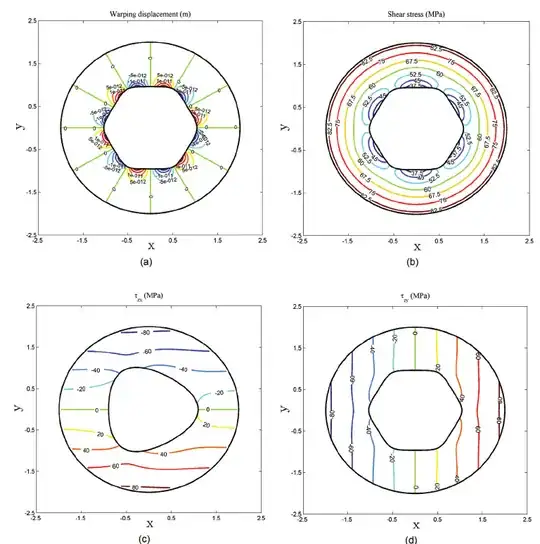

The washer indeed changes the characteristics of a joint. The reason is that the affected area between the nut and the bolt head is not a cylinder but has a frustum/barrel like shape.

Figure 1: Realistic parabolic stress distribution in a preloaded bolted connection (left) and simplified linear stress distribution following VDI 2230 (source:sciencedirect )

When a washer is used the affected diameter will also change correspondingly (i.e. with the washer the diameter increases and so does the overall volume). So the forces are spread over more of the clamped material. The end effect is that the clamped materials appear to be stiffer (in a similar sense that cutting through butter with knife with the edge or the broad side).

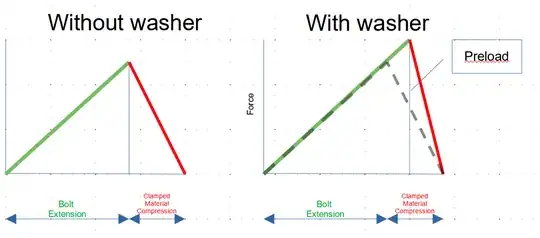

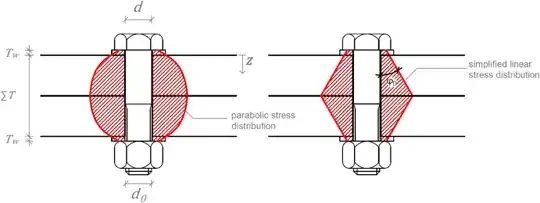

The end result, can be better seen in the joint diagram. (A joint diagram is a means of displaying the load deflection characteristics of the bolt and the material that it clamps. Joint diagrams can be used to assist in visualising how a bolted joint sustains an external force and why the bolt does not sustain the whole of this force.)

Figure 2: Joint diagram comparison without and with washer

With the washer the maximum available preload of the joint increases (for the same number of thread turns).

Why does changing the tightening characteristics reduce stress: (it might not be so obvious) When you use a washer, in the above example essentially what happens is that more of the clamped material engages in the transfer of forces. As a result, the clamped material becomes stiffer than the bolt (hence the change in slope in the diagram above). For a given level of preload force, because more clamped material is engaged (larger crosssection) there are less stresses within the material (the bolt stresses remain the same).