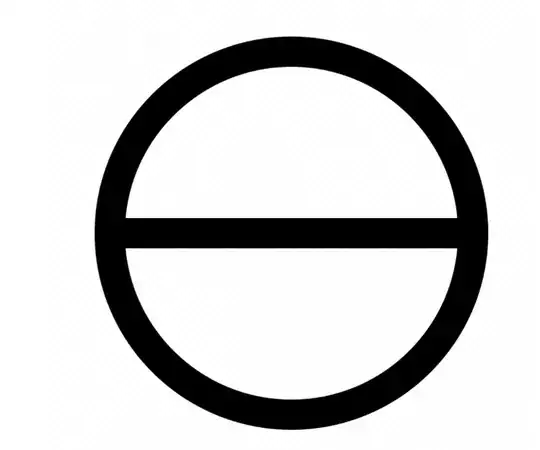

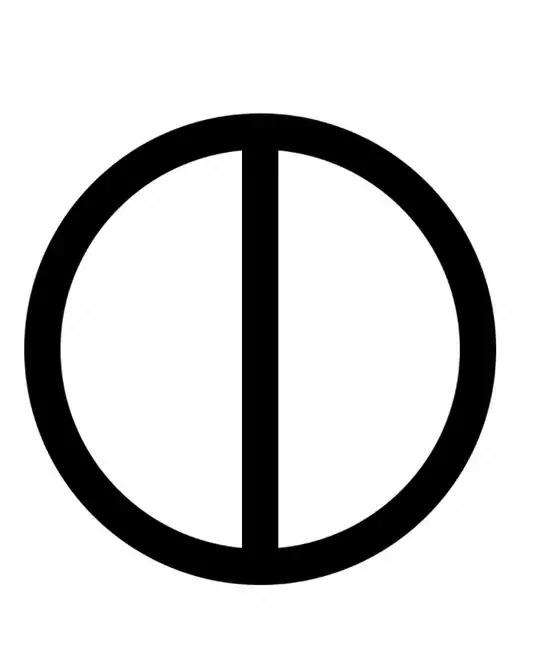

My advice is to change the design if possible from vertical split to horizontal. i.e.

| horizontal |

vertical |

|

|

| Better |

Not so good |

The reason is that :

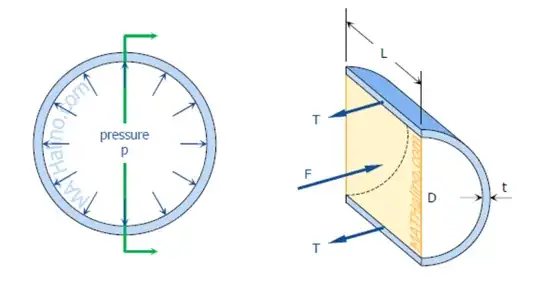

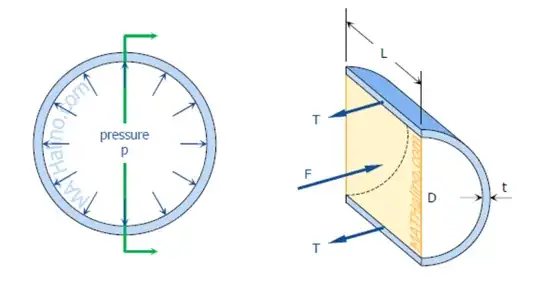

- in the vertical solution the internal pressure will tend to separate the halves

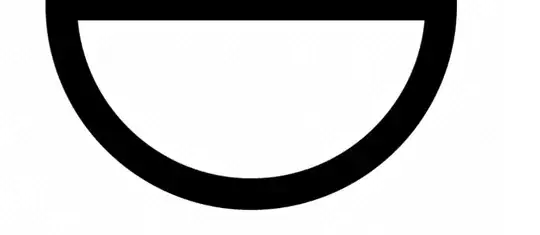

figure 2: Forces developing on a half of cylinder due to internal pressure (source: Mathalino

- you could go for a design that is hemicylindrical (lower part cylinder, top flat). In that version, you wouldn't need to worry so much about sealing if the vessel was static.

figure 4: variation with lower cylinder and top flat

Finally in general the dimensional accuracy of 3D printing does not lend itself for precision sealing. IMHO, it would be best to design perimetrical grooves around the sealing surface and then use an o-ring.

If you are feeling particularly adventure you could design the parts in such a way that they need to slightly deform when you put them together (i.e. they are pushing together). That will help the O-ring perform better.