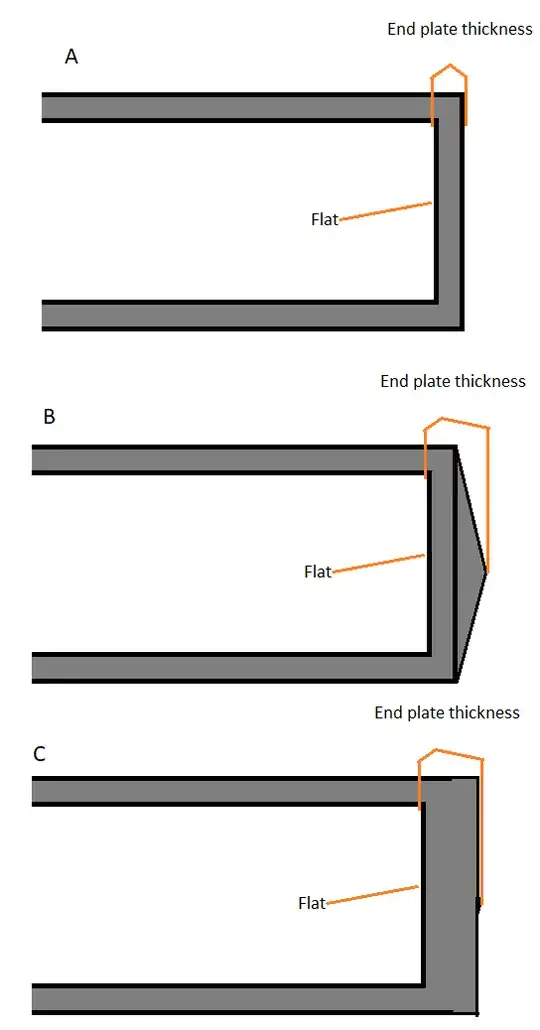

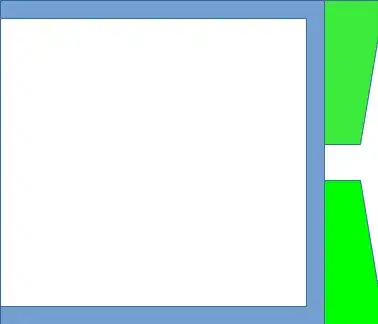

I am making a cylinder of polypropylene that must be pressurized (2 bar). The rough dimensions of the current design (A) are 7 cm tall, 5 cm in diameter, and wall thickness of 1-2 mm. The issue is that the end plate (disc) begins to bulge when the pressure is increased.

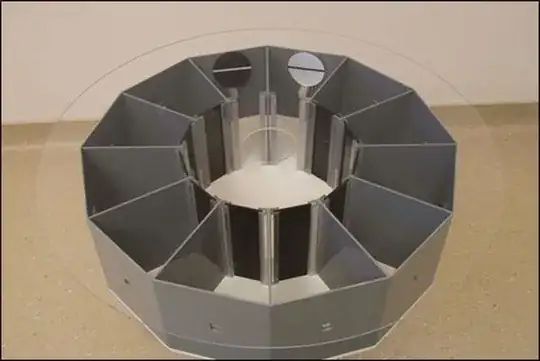

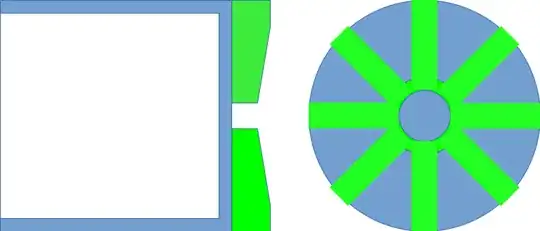

I want to make a new design that is stiffer. Is there a shape/pattern that is better in terms of preventing bulging than naively increasing thickness?

I want to maximize stiffness (prevent bulging) while minimizing the thickness of the end plate. I don't care about how much material I use. I.e. if the stiffness is the same solution B and C are equally good.

Constraints

- The end plate must be flat on the inside, but there are no constraints on the outside shape.

- The final product must be injection moldable.