I have been reading about the elasticity of materials and most often in engineering there is always some ideal concepts which are the extreme cases. So is there any particular definition to what is a perfectly elastic and perfectly plastic material?

Perfectly Elastic Material

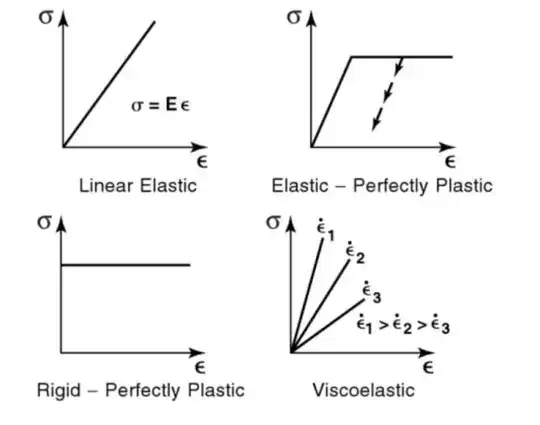

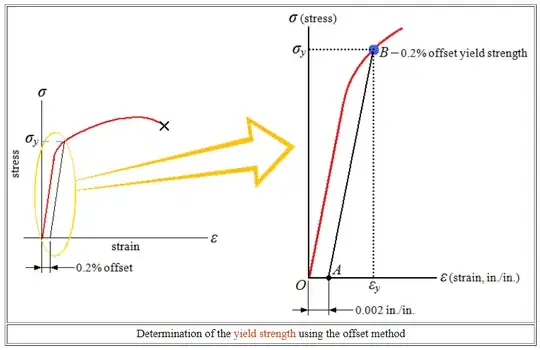

A lot of people say that from material science point of view a more elastic material means the material has greater resistance to elastic deformation eg steel being more elastic than rubber . With that definition ,a perfectly elastic material should then be defined as " a material which suffers zero deformation under any value stress (within elastic limit)". But in this case it becomes similar to the definition of a rigid body , which is "a body that suffers no deformation under stress".

Yet another possible definition could be that a perfectly elastic material is one which behaves as an elastic material over its entire stress-strain curve i.e behaves as an elastic material till fracture. Here then we could have perfectly linear elastic material and perfectly non-linear elastic material.

Perfectly Plastic Material

A perfectly plastic body could be defined as one which produces no restoring force for any value of stress applied. Thus a perfectly plastic body would always suffer permanent deformation for any value of load applied or in other words a perfectly plastic body would show plastic behaviour throughout the stress-strain curve.

If perfectly plastic and perfectly elastic are well defined ,how would their stress-strain curve look like?