OP injection molding tag is correct. OBall uses injection molding and plastic welding.

The OBall is the invention of David E. Silverglate.

Toy Ball Apparatus with Reduced Part Count

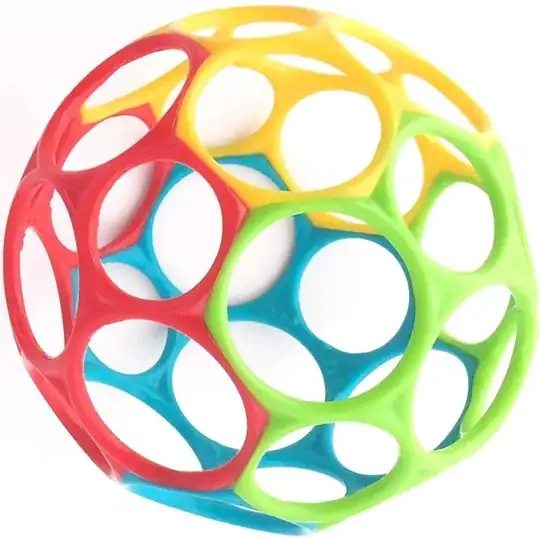

Reduced image from Kids II.

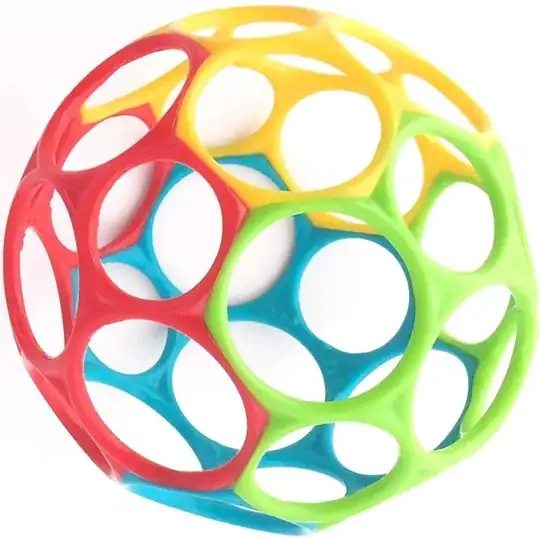

It consists of four identical, flat, injection molded, pentagon and hexagon shapes with circular (or elipitical) holes, which are shaped and plastically welded into spheres.

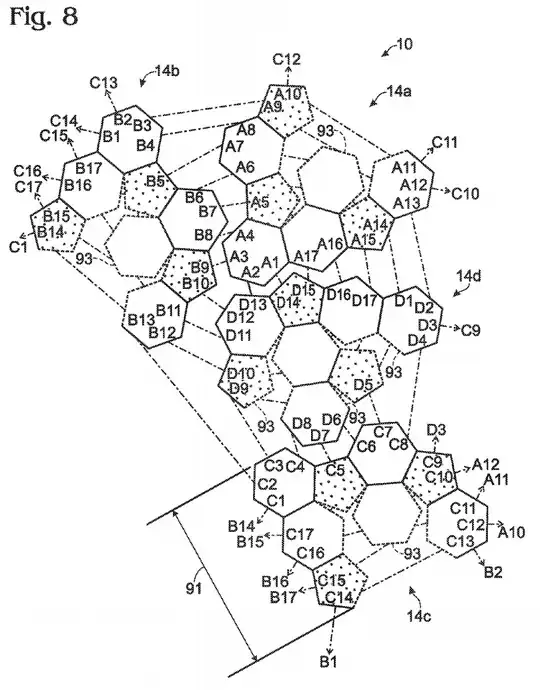

Pentagon and hexagon edges are the same size and individual connected circles are only connected along one edge. The four shapes are clearly shown in colors above and from the patent. Solid lines on each part are hard connections, while dashed lines represent connections within the part. Patent shows how individual edges on parts are interconnected. Injection molding with a plastic (PETE [or PET] from Jim Clark link: What is Oball made of?) at a higher melting material and welded with a plastic at a lower melting material.

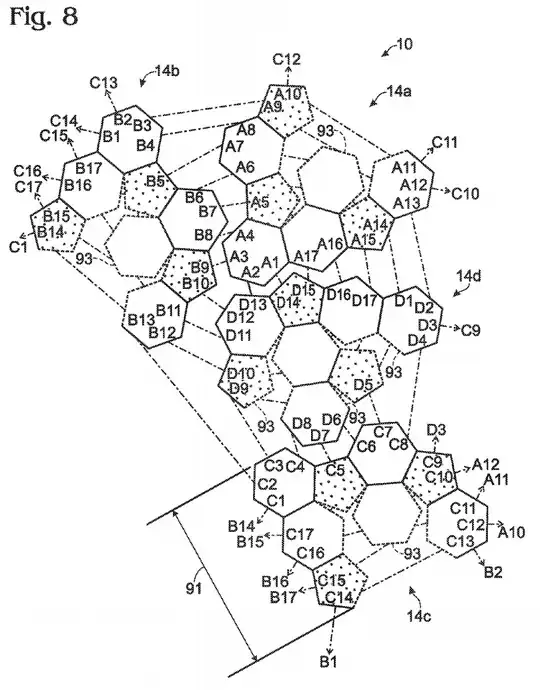

Figure 8 from the patent.

[0022] The shape and number of the mesh components 14 are designed in a manner that decreases manufacturing costs incurred using a process such as injection molding. Regarding the number of mesh components 14, it will be appreciated that when four mesh components 14 are utilized the production time may be significantly reduced when compared to a toy ball apparatus 10 having ten mesh components. The decreased production time may in turn decrease the toy ball apparatus's manufacturing cost.

[0029] FIG. 9 illustrates toy ball apparatus 10 in its assembled State, in which the plurality of mesh components 14a, 14b, 14c, and 14d have been coupled to enclose the closed Volume 20 and form the mesh 12, by joining adjacent mesh components 14 along their cooperative mating Surfaces 19 and securing the mesh components 14 together, for example, by plastically welding the mesh components 14 together along the cooperative mating Surfaces 19.

Each part has 3 pentagons and 5 hexagons.

Clearly Part B and C are the same. But A and D are obfuscated by the patent lawyers. Edge numbering indicates they knew all parts were the same. They just divided it to obscure the true inovation.

In all 4 parts, central hexagon has no writing on it. It is surrounded by 3 pentagons and 3 hexagons. The final hexagon with A1,A2,A3&A4 (or B1,B2,B3&B4, etc.) connections are always connected to hexagon with A16&A17 (or B16&B17, etc.) connections.

So tooling is for one part, which means true inovation was making ball from 4 identical flat injection molded parts.

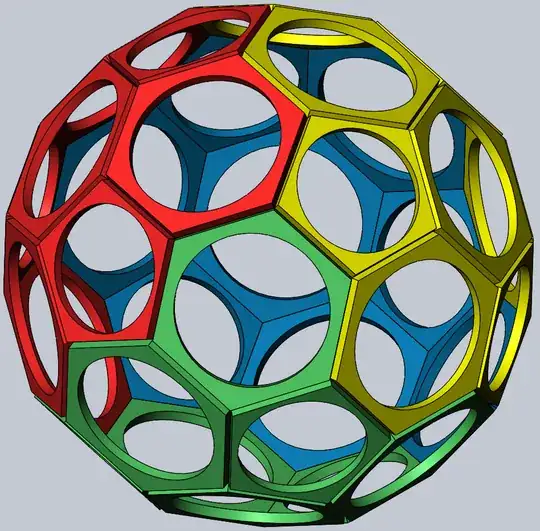

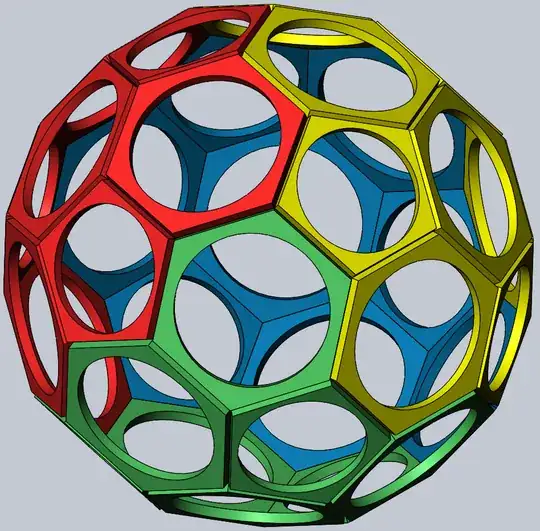

SolidWorks drawing of ball made from 4 identical parts.