I am not a mech engineer and have been struggling with this for a while, I feel like it is pretty straight forward but I'm missing something.

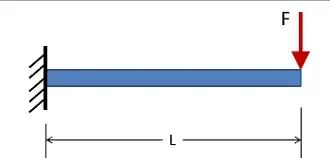

The problem is a horizontal tube that is supported at one end with the weight on the other end. My specs are length of 3 ft, outer diameter of around 2 inches, and a force of 120 lbs.

Basically I want to figure out the optimal outer diameter (2 inches +- .5 inches or so) and minimal wall thickness. (The cheapest tube)

I can get tensile strength from most carbon fiber tube manufacturers.

I believe I want to calculate maximum stress and more specifically sheer stress for a hollow tube. But I haven't been able to find the calculations that are in terms of tensile strength.

Any pointers or references in the right direction would be awesome!