I have a 6" x 6" x 1/4" piece of carbon filled teflon that is slightly curved (I think it must have come off an roll of enormous diameter) that I need to flatten. The carbon fill is carbon black, not carbon fiber, in order to make the material static dissipative.

Is there any good procedure to flatten it like with an iron?

Alternatively, thickness is not too important so in theory I could try stoning it to flatten. I will have to at some point to remove scratches on the surface but I imagine it will glaze the stone like nothing else and I don't want to need to stone too much of it since this material produces nasty dust.

With a chord of 6", there is a distance of about 2mm to the circumference so it would turn the 6mm plate into a 2-3mm plate if I were to stone it down to flatten it, which is fine if it were not for all the work involved and dust that would be produced.

UPDATE: Stoning does nothing. Just messes up the stone. But wet sanding with Scotch-Brite 7447 (Maroon) cleans up scratches and imperfections real nicely. A circular motion produces a very nice matte finish. Finer grades would probably produce a finer finish. Doesn't flatten it though.

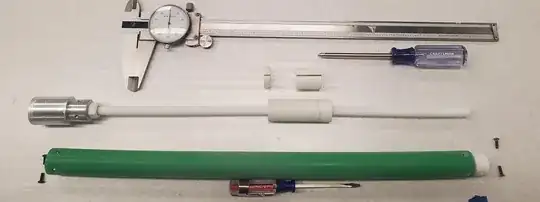

UPDATE: Glass transition temperature is 120C so I think I'll try to heat it up beyond that. This is going to be used to make really thick 2" diameter washers. So I think I will cut out oversized square pieces, mount them on a big bolt with 2" steel washers separating them, maybe with a spring to continuously apply force and then put the whole thing in an oven at 150C or so...if I can get the oven to get that low.