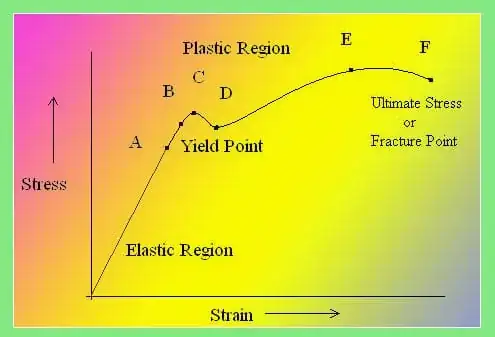

Summary: There is increasing plastic behavior and decreasing elastic behavior as the sample is strained from B to C. The transition is caused by random grain orientations and variable resolved shear stress.

With respect, the other answers generally have the right idea, but are missing the important meso-scale mechanism for why there is a non-linear shape between points B and C.

Between points B and C on the stress-strain diagram there is a transition from elastic stretch to plastic flow. The transition occurs because bulk metals are typically composed of many randomly-oriented crystal grains. As you may know, metal crystal grains flow by application of shear stress. The resolved shear stresses on the crystal grain slip systems is what matters for initiating plastic flow. Grains at different orientations experience different resolved shear stresses. Grains more "favorably" oriented, with larger resolved stresses, experience plastic flow earlier. Because grain orientations are random, each grain will start to flow at a specific stress level, giving a distribution of stresses from point B to C. At the macro-scale the distribution means that the sample gradually transitions from "no plastic flow" at point B to "all flow" at C.

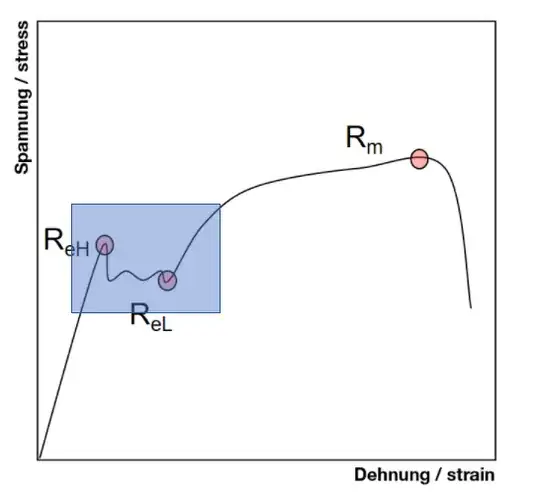

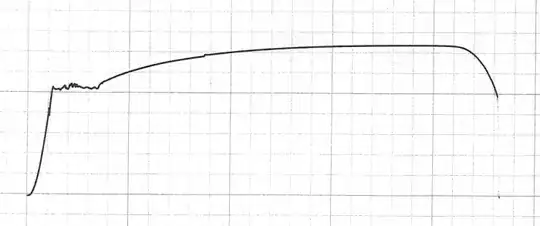

At least, until unlocking of interstitial atoms trapped at dislocations starts to occur between points C and D. See this QA for reasons why D is at lower stress than C, and for why NMech's answer plot is shaped the way it is.

For a little discussion of resolved shear stresses see this QA.