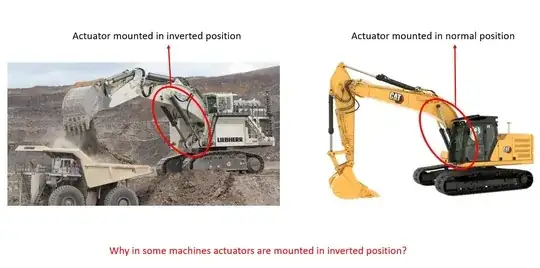

Everyone keeps mentioning ease of hydraulic connections, but one could alternatively design the hydraulics to fit the cylinder orientation, yet it is almost never done. This is partially because there is little difference for the cylinders themselves. Consider at least one more step in why the hydraulics might be designed as they are. Here is one possible consideration.

For the Caterpillar pictured, the circled cylinder and associated hoses are easy to service. The adjacent one might be slightly more difficult.

If however you had to replace all sets of hoses, then the Liebherr design might actually come out ahead compared to an equivalent sized machine built in the Cat configuration. This is because a lot more is in a common area to all 3 cylinders on the Liebherr.

Why would someone prefer one over the other?

Mine/quarry bottleneck can be the transportation of material out, meaning missing a single shipment is a considerable cost compared to hoses. Delaying a train by a few hours to make your quota? It could affect the whole line and everyone using those tracks. Delaying a truck? It'll take the same amount of time to make the round trip anyway so it will remain behind forevermore. If you're replacing one, might as well replace even slightly worn ones rather than using the full life of the hose.

Renting out or owning construction equipment? Even if someone has to fix a down machine, work (or rentals) can still go on as long as your plan was flexible enough. Using the full life of equipment just makes sense.