I am trying to create a prototype for a gravity energy storage system, and I need to release potential energy stored in a heavy load of mass M, raised to a height *H.

I intend to use the mass traversing the length, to drive a piston, which pushes upon a hydraulic fluid to turn the P.E into K.E.

I am at a loss as to what mechanism I can use to efficiently (and simply) translate the descent into a vertical movement of the piston - since the piston will be contained in a sealed cylinder.

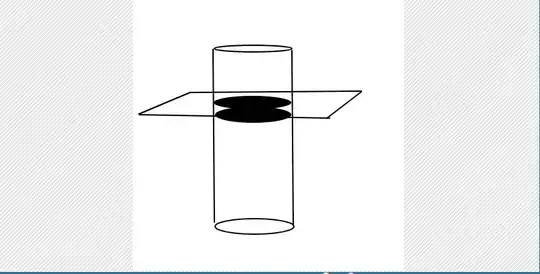

I have included a rather crude sketch below:

Where:

- The parallelogram represents the load bearing surface,

- The two dark circles represent the piston/plunger

My question is this: Is there a mechanism that allows a plunger/piston to be moved along an axis WITHIN a cylinder, by means of external force applied OUTSIDE the cylinder containing the piston?

I think what I'm looking for is some kind of telescopic mechanism.