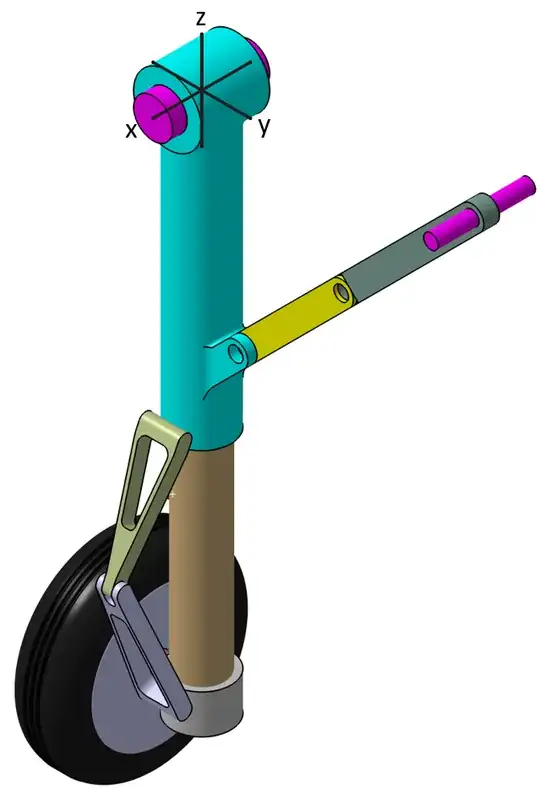

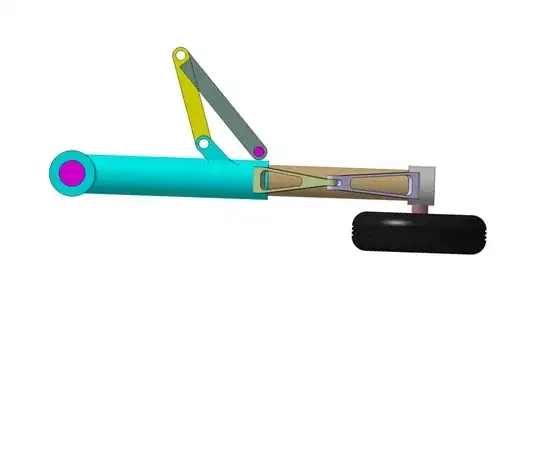

I want to design a rotational lock mechanism for the landing gear of an aircraft. It's function is to make sure the landing gear stays folded when the aircraft is on air and the landing gear's position is not changed due to external forces.

An electric motor will be used.

When the aircraft is landing, the lock will be deactivated and landing gear unfold. For that purpose, I will use this rotational lock mechanism to keep it locked in folded or unfolded position.

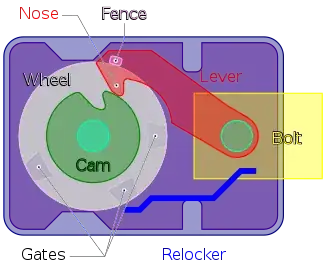

But the problem here is that this is able to rotate only clockwise, which means, once it gets locked the landing gear can't unfold.

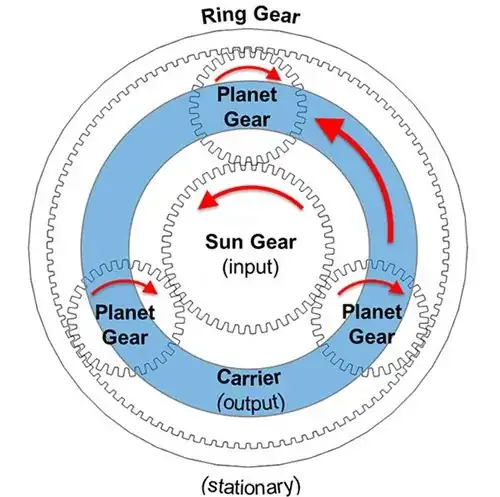

To overcome this issue, I want to use a reverse planet gear mechanism, similar to those in automatic transmissions.

I will add a clutch pack to this reverse planet and it will be like an optional path in power transmission route.

When I want to fold the landing gear, the clutch pack of the reverse planet stays deactivated and landing gear shaft rotates in the same direction as the lock wheel does.

When I want to unfold the landing gear, the clutch pack of the reverse planet applies and landing gear shaft rotates in the opposite direction as the lock wheel does.

By using these two mechanisms together, I will make sure the lock wheel always rotates clockwise no matter what direction the landing gear shaft rotates.

I want to know if you guys have a better idea or if there are generally accepted engineering designs to prevent rotational movement. Nothing here is a solid design constraint. I am just brainstorming here. You can suggest a different mechanism for rotational lock.