I am building this ground-mounted solar panel sail:

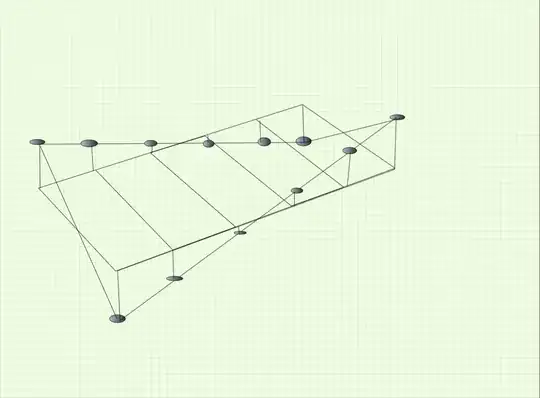

It will sit on twelve 150 mm timber piles. There are 20 panels 1755×1038 mm, 20 kg each, with 17 mm gaps between them, sitting at 69°. The total weight above the timber (panels + aluminium frame) is roughly 550 kg.

The piles are 2.4 m long, and they will be in the ground 1.2–1.5 m deep.

The triangle base is 2.23 m, height 2.91 m and side 3.11 m.

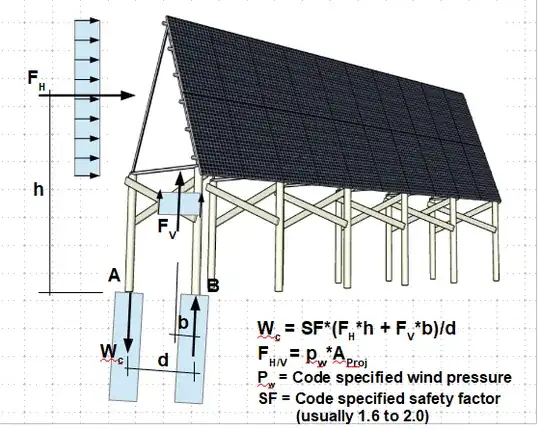

The question is how heavy the piles' feet (not on the picture) need to be to stop the sail from flying away when it storms. The goal is to ensure that a storm would rather rip the structure apart than lift/tip/fly it. Occasionally winds may top 150 km/h in this area.

I've asked a professional structural engineer this question and he's given me this figure of at least 0.6 m3 of concrete per pile.

Assuming density 2.4 t/m3, that means a weight of more than 17 tonnes is required to hold the structure down.

Does the weight figure not sound overestimated? Would a wind be able to come any close to lifting that weight by blowing in the back of this sail before it rips it apart?

Also, will the cross beams between the piles do a good job? My assumption was that they should provide robustness to the structure so that it should not be possible to lift the rear row of piles without lifting the front one to the same distance.