This is a question for engineers working in diesel engine design or tribology. I am doing up an analytics dashboard for my father who analyses oil samples of heavy mining equipment. The diesel fitters there have moved to a calendar based maintenance system instead of hours based which means many machines are being serviced before they need to be or well after.

One of my goals is to help him quantify how much it is costing them when they change out the oil after the recommended change out hours. I figured that Hastings Deering (CAT dealer) would have some figures on this (they do all the actual sample analysis of the oil), but I am not sure what they would call it. I think the best way to represent this would be through the reduction in engine life for every hour the engine runs over the recommended oil change out time. This wouldn't be linear but should only need one variable being hours. I just don't know what to ask Hastings for though, what terminology to use.

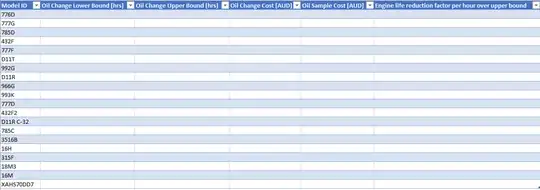

Anyone have any suggestions? The image below is the info I planned to ask them for.