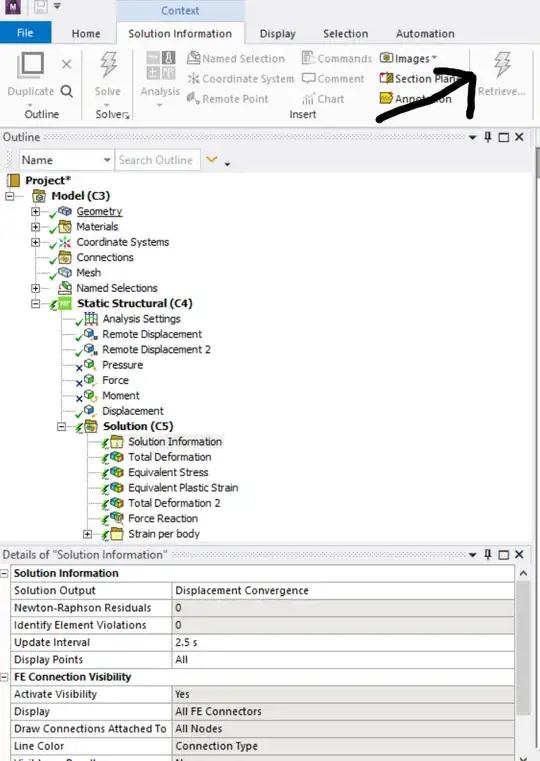

I am currently conducting a static structural analysis study in Ansys and encountered convergence prolems.

I have a very large thermal gradient (almost 600°C) as input from a precedent transient thermal analysis which I apply gradually. I am looking to analyse thermally induced stresses. Large deformationas are turned on.

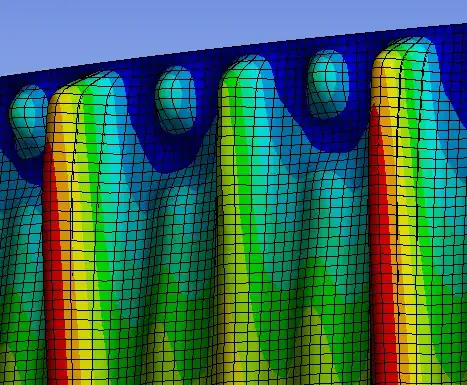

The model constists only of shell elements which are connected by MPCs (defined as bonded and sticking according to solution output). I have fixed supports and I am making use of cyclic symmetry. So naturally, my model is over-constrained. Running static structural analysis with only mechanical loads and without thermal gradient converges quickly and without any problems.

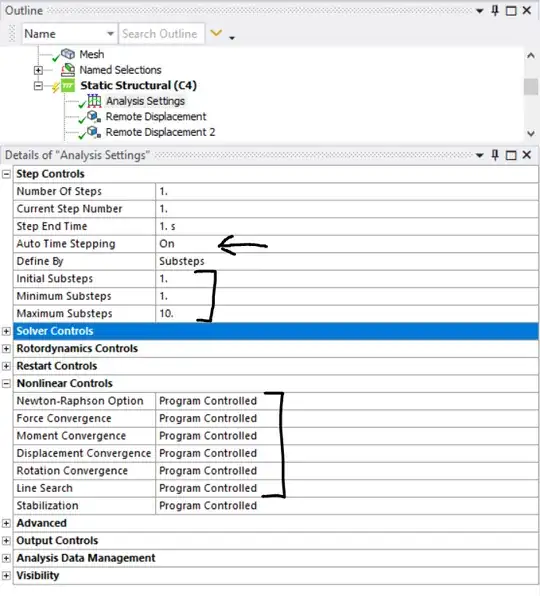

The problem does not converge oncy I apply the thermal input. I already tried reducing time step sizes to a minimum of 0,001s (1/100 of time step). Reducing mesh sizing did not help convergence either and only steps up calculation time drastically.

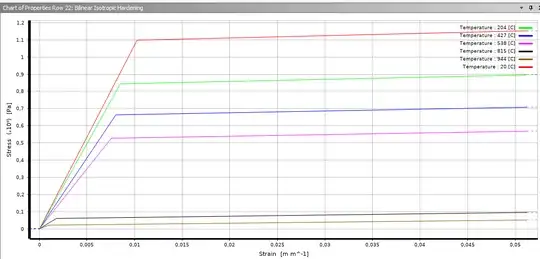

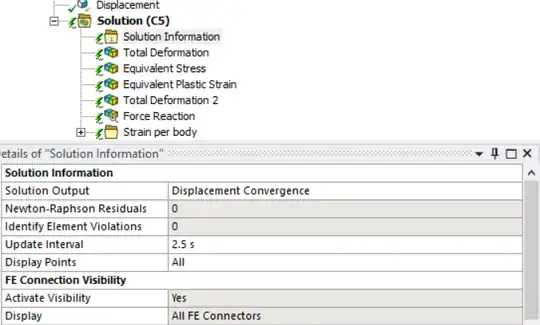

Unfortuntely, I cannot review Newton Raphson Residuals since I am conducting calculations on a cluster and can only download solution files which I then input into Workbench Mechanical Application. (Or is there a way to do so?) But I can view the solution at the last time step before non-convergence occured. I observed that the problem failed at similar step times which correspond to a max. temperature of around 300°C (no matter the mesh size or minimum time step size). Max. equivalent stresses are 8,07E8 Pa. Looking at material data, one can say that yield stress is surpassed and plastic deformation occurs. I therefore have additional material non-linearities. I suspect that this is causing my convergence problem.

Does anyone know if the stress-strain curve actually continues where the dotted line is shown and data are given? I suspect that it does since bilinear isotropic hardening is defined by tangent modulus.

The only error message I obtained at some point (only in one try-out) was that there is exsessive thickness change. No other error messages (of distored elements or similar) show.

Does someone have an idea how I could obtain convergence in this model or what else I could try to analyse the issue? I would be very thankful!