Seemingly no flood of answers. You get one which is simplified from a noise making toy named "cog rattle" or "ratchet"

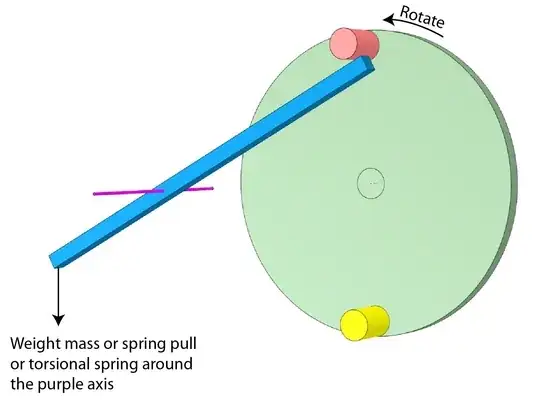

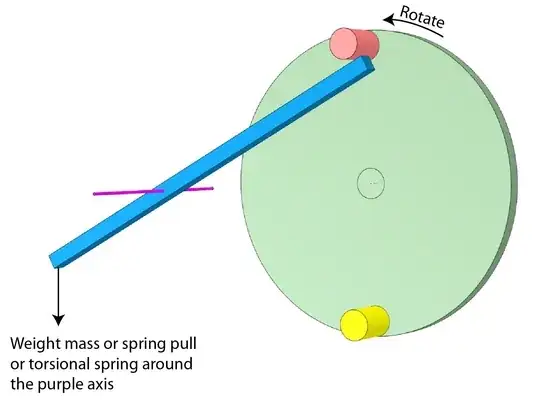

The red peg is just starting to push down the rightmost end of the blue bar. The rotation needs some force because there's a down pulling spring, a counterweight or a torsional spring which tries to rotate the bar counterclockwise around the purple axis.

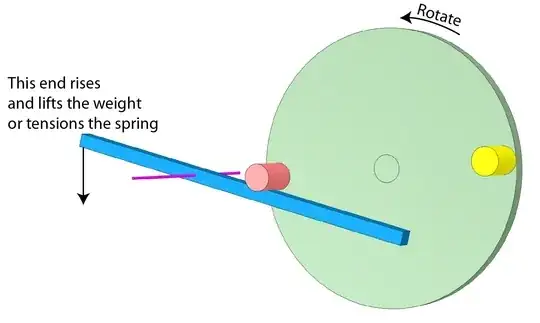

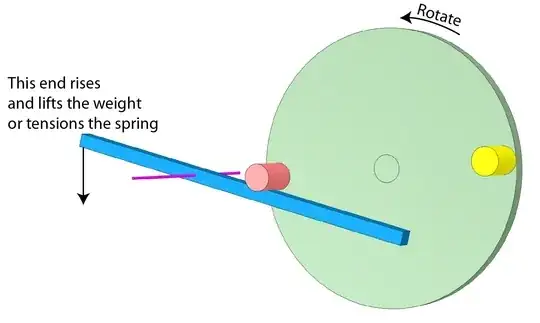

In the next image the green disk has rotated 90 degrees CCW, so the blue bar has turned about 50% of its range.

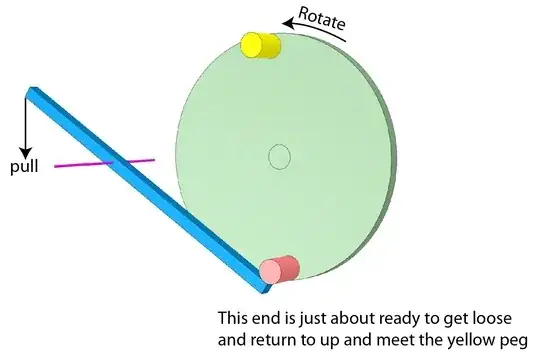

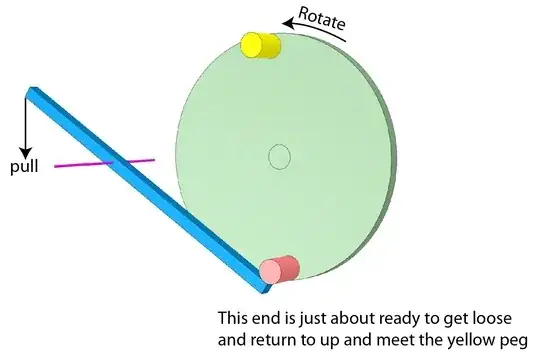

In the next image the blue bar is in its extreme position. When the green wheel rotates a little more the bar returns to its initial position (= pulled by the gravity or a spring):

The left end of the blue bar could be the needle of your linked meter. In that case the counterweight or down pulling tension spring must be replaced by a spiral or torsional spring which generates the needed return torque around the purple axis.

BTW the numeric scale of the needle isn't linear with this method. Every shown needle position value must be calculated separately.

The practical turning range of the blue bar is much less than 180 degrees. If you need more, for ex. 270 degrees, the blue bar cannot be the needle. You need a gearbox or lever to extend the range.