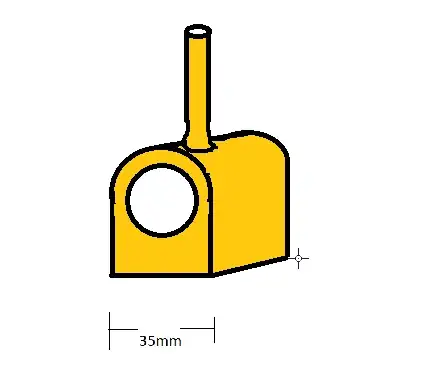

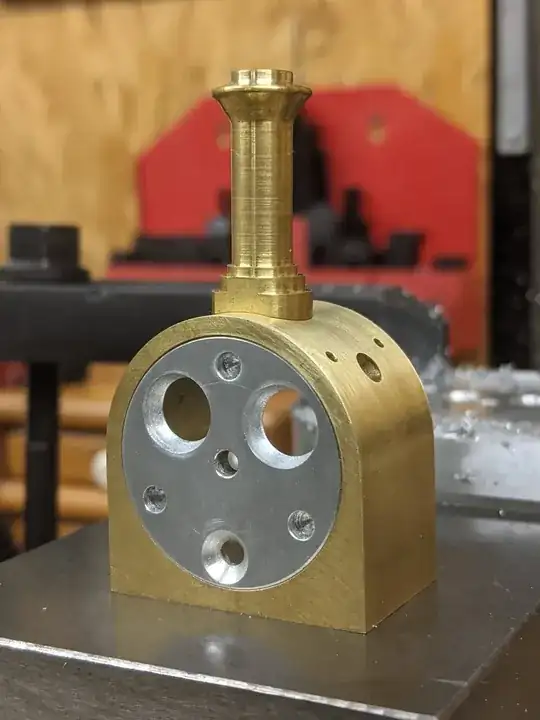

I have a job where I need to solder a brass tube at a precision 90 degree perpendicular angle to a piece of round stock. My current idea was to use a spring loaded center to hold the tube upright at a precision angle for solder application in my mill.

It seems that the vice jaws and the base of the vice are enormous heat sinks which is obvious and I just can't get the brass components up to temperature with my small butane torch (all I have). I've considered using ceramic fiber insulation between the vice jaws and the base of the work, but I'm concerned that the fabric-like material will cause the work to not be held straight in the vice.

What are some options to overcome these challenges? Are there better ways to hold a tube at the 90 degree angle? Better insulating materials I can use?

I wanted to add a soldering tag to this question but one doesn't seem to exist and I don't have the rep to create one so I put it under welding at risk of being crucified.