Context

Even major bicycle corporations have the occasional product recall on handlebars.

It's easy to see why. The bike itself is a gentle, light, and nimble ~10 kg (for a road bike) object, whereas the weight of the brute riding it is anywhere from 50 kg to 100+ kg, and if the cyclist doesn't rise before hitting bumps, the frame is subjected to considerable stresses. The stresses are most worrisome on the handlebar (and the seatpost).

The handlebar can be roughly modeled as a beam with two 20 kg weights at each end, and a 40 kg supporting load at the center.

But that's without any impacts. Either way the stresses spike at the stem-handlebar interface, and their starting values are already nontrivial because the handlebar must be firmly clamped at the stem.

Carbon on bicycles is, as cyclists like to repeat often and in unison, not a spontaneously explosive material. Still, anyone who has followed a serious bicycle race will have witnessed live the spectacular ways that carbon frames can fail. You don't want that to happen to your handlebar.

This is one of the reasons why the bicycle industry has moved on mountain bikes from a 31.8 mm diameter for the stem-to-handlebar connection. On mountain bikes that diameter is now used only for lower-market bicycles. The trend is moving towards 35 mm diameter at the stem-handlebar interface.

Statement

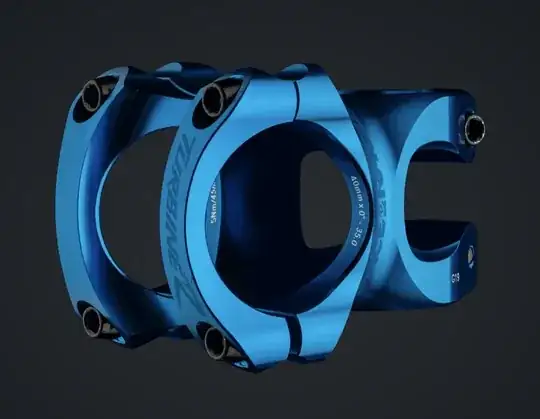

The stems on the market are of two designs.

The dominant one is an open-front design.

The alternative is a closed-front design.

Either way, the backside of the stem (the one on the side of the cyclist) is always open.

Especially for a carbon handlebar since the recommended torque of stem bolts is often much lower than that for an alloy handlebar, it would seem that the closed-front design is superior. It distributes the grasping stresses on a larger area. (A special gritty paste is usually required to make a firm connection possible using lower bolt torques.) Indeed, it would appear that a closed-from-both-sides design would be even better.

Why is the open-front bike stem design so widespread despite that it may be inferior to the closed-front design?

The only explanation I gather why the open-front design suffices is that nothing is rigid. Even steel ball bearings, which we imagine are a rigid object, do not generate stresses that shoot towards infinity. When loaded, they behave just like a rubber ball. They can be squished.

Here also, the two pairs of bolts will generate the dominant stresses on the two narrow vertical bands—regardless of whether the center section is present in the stem. If it's present, it will take relatively little load, and it can hence be discarded. The presence of the mid-section may simply be cosmetic.

Can you confirm/refute and/or elaborate?

Future Questions

- Normally shims are only needed to use a larger-diameter stem. Might shims be used to better distribute the load and enable rougher riding with less concern of using dental insurance?