The bicycle component manufacturer Shimano makes crankarms named "Hollowtech".

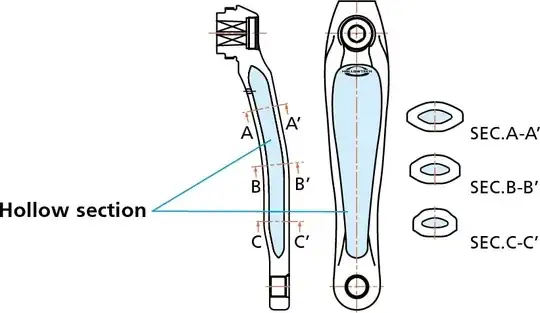

Hollowtech crankarms are meant to be both strong and light. As the diagram below (source: Shimano) shows, the outer shell is made from an aluminum alloy and the inside is hollow.

On closer look it turns out that the cross-section of the crankarm is not made from a box section, but from two C-sections. (Source: bikeradar)

Another (older) style of Hollowtech consisted of a C-section closed off by a plate.

The two parts are glued using epoxy. It's understood that epoxy, once it sets, is more than adequate for the task of carrying the weight of a cyclist on the crankarm, but even if epoxy does bind well with a (perhaps roughened) alloy, wouldn't the difference in the stress-strain curves of the two materials mean that when the alloy bends, it is the epoxy that will take all of the load? Since it's used here only as a binding agent, it would appear this is a recipe for failure. Do you understand how epoxy can reliably bind two parts of a crank arm, and can you explain it?