I have two results that don't seem to match up and I can't figure out why.

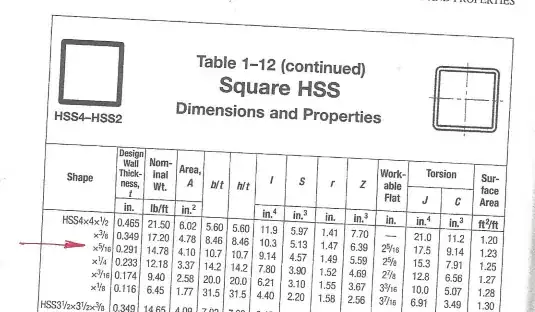

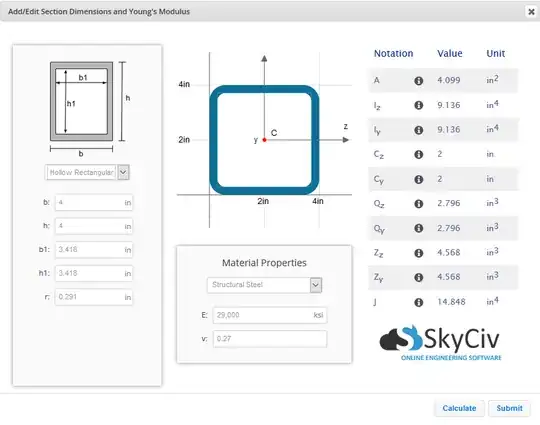

I built a hollow square section (HSS) using two different structural analysis softwares (they both agreed). However, they don't seem to agree with the AISC steel table despite the dimensions being identical. It seems to be the Torsion Constant (J) which is slightly off in the table.

What could be the possible reason for this as I am totally stumped?