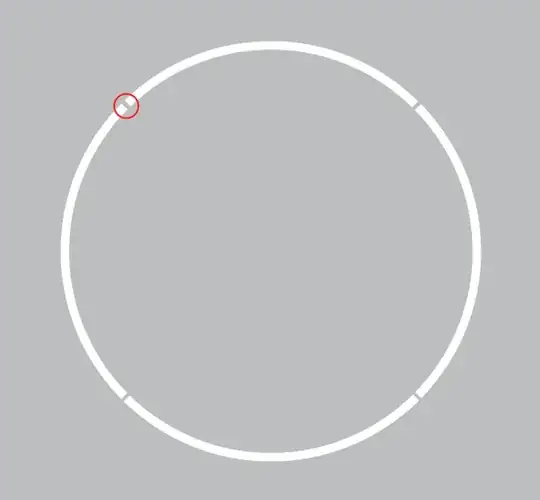

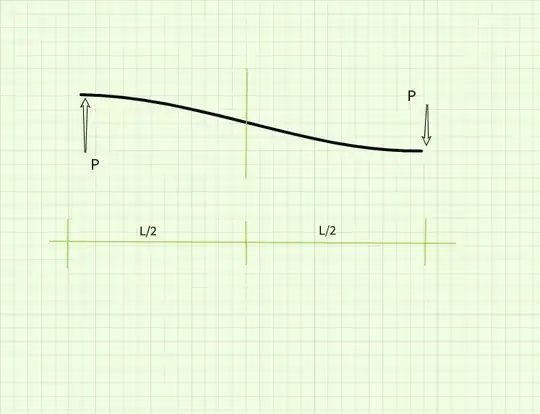

In the image is a design for a chemical etched piece of metal. Shown in white are holes formed in a sheet of metal, which is shown in grey. Highlighted in the red circle is one of four sections that connect the circular shape in the centre to the rest of the sheet, which is larger than shown in the image. In order to prevent these connecting sections breaking under the weight of the circular shape, how can the required thickness vs length of these connecting sections be calculated?

The thickness of the metal sheet is known. The weight of the circular shape is known. The flexural strength, tensile strength and shear strength of the material is known. Can a safe working minimum thickness, and maximum length for the four connecting sections be calculated, or estimated based on this information?