Radial lacing "tortures" the spokes of the wheel because when torque needs to be transferred from the hub to the ring when accelerating (or from ther ring to the hub during braking).

| Radial no load |

Radial with torque |

|

|

I.e. if radial lacing is used then the spokes would need to act as beams transferring a bending moment (but their second moment of area is really small so they would deform and result in a pattern similar to cross lacing).

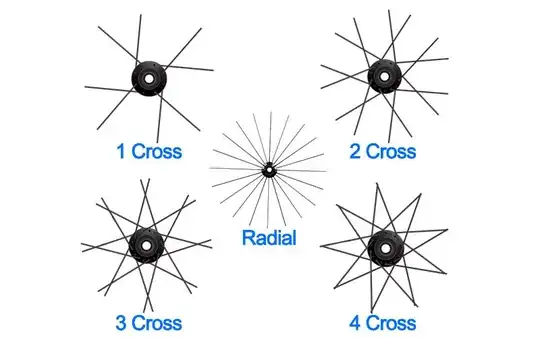

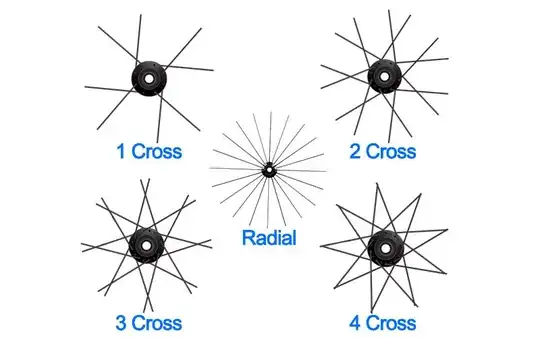

The Different patterns of lacing (Two cross, 3 cross etc), by having an offset from the center of the wheel, they allow the carrying elements to act more ("more" is the essential word here) as rods (elements carrying only axial forces). (The cross parameter improves the geometric stability of the pattern).

Figure: Different lacing patterns (source: best wheel set)

Figure: Different lacing patterns (source: best wheel set)

That is the reason that probably this watermill has this shape (although most surviving watermills are designed by wood beams with enough cross-section that gives them a second moment of area that doesn't allow much deformation). However, the wooden beams are in stark contrast to the spokes of a bicycle wheel in terms of second moment of area.