I have a very basic understanding of how gears work, and while trying to learn more, I've run into a small point of confusion.

If a 2:1 gear ratio is achieved by having twice as many teeth on one gear than the other, then how are 250:1 ratios achieved? Certainly there aren't gears with 2500 teeth on one gear, and 10 on the other...

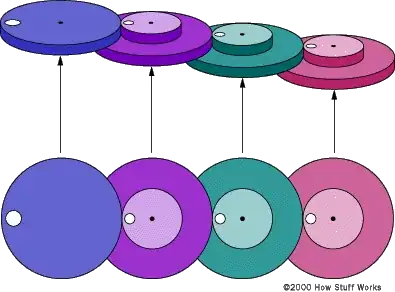

For example, here's a very tiny motor with a 250:1 gear ratio: DC Motor with Gearhead