Wow, tungsten, huh? Whenever I see exotic materials, usually a design mistake is being made. The other answer by starrise is wrong for various reasons. Counterbores are normally only used for making sockets, not boring blind holes.

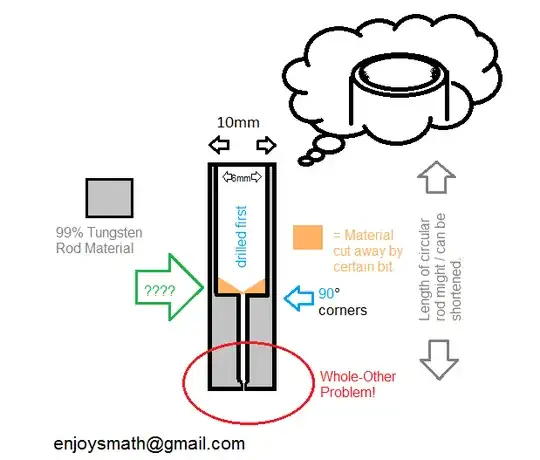

If you actually want to do this, the right strategy would be to set up the work piece in a four-jaw chuck on a lathe and rough the bore with a carbide jobbing drill mounted in the footstock.

Your next step will be to dress a cylindrical form in Aluminum Oxide J 40-60 grit using a rotary dresser. Mount the form in the tailstock of the lathe and then finish the hole. Clean the lathe carefully, because now it will have grit all over it. If your bore needs to have a good finish (not apparent that it does, given what you have written so far), you can repeat the process with a 200 grit form.

Next you need to get an extension mount for your tailstock and mount a smaller diameter carbide drill to rough the small bore. Once again use a grinding form to finish the small bore. Depending on the tolerance of the small bore you will probably need to redress the form because it will wear down as it grinds out the bore.

Obviously everything needs to be concentric all the time, so you have to be checking runout carefully on every step.

All this work can be also be done in a drill press (or mill) if you make a suitable workholding fixture. Using a drill press or mill your maximum precision will be 0.005" and 0.002" respectively. A lathe will be 0.0002".