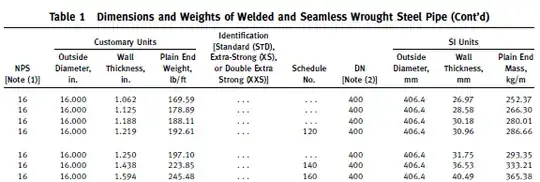

The TurkStream project site claims the gas pipeline will use pipes made from 39 millimeters of high-quality carbon manganese steel with additional plastic coatings on both sides. Yes, they claim 39 millimeters (roughly 1,54 inches) of steel walls - that's a whole lot of steel! For comparison, the M41 Walker Bulldog light tank had only 38 mm of armor plating.

Is such wall thickness realistic for an industrial gas pipeline? Why would you need that much steel for a gas pipeline?