Pressure is force/area, if the area offered by the pump impeller is smaller than the area against wich the steam must force its way out of the boiler, and both the turbine and the pump are linked, then, the same pressure will result in a smaller force on the pump than on the turbine.

Example :

Lets suppose that the pump is a piston pump, and on the steam side there is a piston engine (for simplicity). In a certain part of the cycle, both the pump piston and the engine piston valves are open towards the boiler (the pump is feeding water to the boiler and the engine is taking steam from the boiler).

The "face" of the pump piston has, lets say, a surface area of 10cm², while the steam engine piston has a surface area of 100cm². Lets suppose the pressure on the boiler is 200kPascal. This means that the pump piston will need to force its way against 200000N/M² * 0.001M² = 200N of force. While this pressure on the steam engine produces 200000N/M² * 0.1M² = 20kN. It's clear that in a direct linkage between the pump and the engine, the steam engine will produce much more force than the pump needs to feed water inside the boiler against the pressure gradient.

For comparision, lets suppose that instead of pumping water into the boiler, the pump takes steam and pumps it into the boiler. If the pump piston is smaller (meaning a smaller stroke or bore), the amount of water mass that gets out of the boiler via the engine would be bigger than the amount of mass that gets back into the boiler via the pump. If both where equal the engine would not generate any power. While if the pump were able to put more steam into the boiler than it were to get out, you would have an above unit power source - i.e. defying the laws of thermodynamics. Soon the boiler would run out of mass to heat.

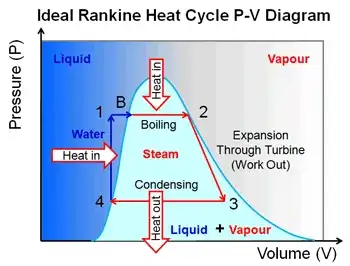

But, as what gets pumped inside the boiler is liquid water, and water as a liquid has a much higher density than steam (meaning the same volume holds more mass as liquid than as gas - besides the fact that liquids have a fixed volume while the gas can expand), when that small volume is pumped into the boiler as water, the thermal energy added to the system will expand this mass into a steam that has a lot of pressure and much less density, so to get the same mass of water (as steam) out of the boiler via the engine, you will need a much bigger swept volume than the one you used to put that water inside, resulting in a difference in forces exerted by this gas over the piston of the pump (via the incoming water column) versus the engine piston, deciding the direction towards wich the system will move.

Got the idea ?

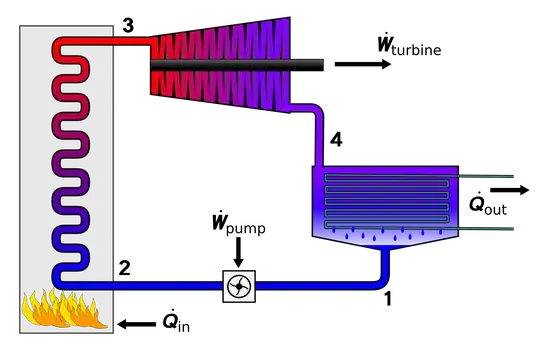

In other words, the ability of the water to change phase and occupy a bigger volume than the fixed volume liquid results in a net power gain into this system. From where comes the energy to cause the phase change, which then causes thisincrease in pressure? It's from the heat source. Where goes the energy rejected? It goes out of the condenser, where steam becomes liquid, losing volume, to be injected again into the boiler as a smaller and fixed volume liquid, and so on...

The key idea here is pressure equals force divided by area.