Well, while searching for dielectric elastomer actuators I can find that they normally have efficiencies around 80% or more (source page 38), they are cheap and easy to build.

But the more I search about them, the more I notice that I can't find projects more complex than proofs of concept and others uses, like microfluidic pumps.

Why is this lack of interest on actually using this class of actuators on more elaborated robots? What I'm missing?

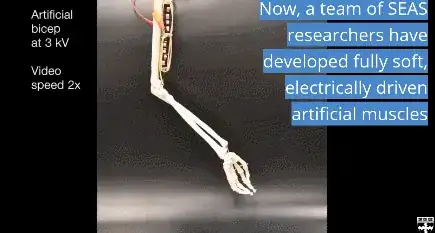

This is the only example that I could find (source).