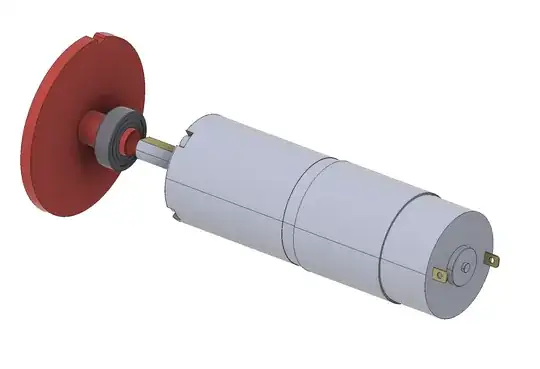

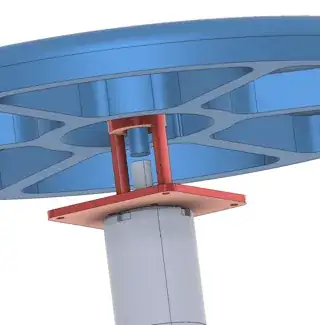

I have a gear with a D-shaft that is intended to directly drive a turntable. Something relatively heavy at very low speeds and with not much torque, if it's important.

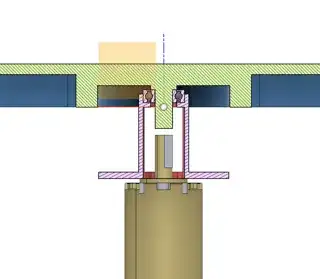

I really don't want the gear to take the weight of the load, so i want to put a ball bearing between them. So now i am drawing a shaft that comes out of the turntable and goes through the bearing, and has a D-shaped hole in it.

Problem 1: the D-shaped hole requires some fillets as i understand the production - but also small fillet radius is not liked by the manufacturers.

Problem 2: the shaft diameter is 8mm, the bearing bore diameter is 9mm. So that leaves me only 0.5mm thick tube for the D-hole. Seems too thin. Larger bearing is a problem because then i don't know how to mount the motor.

upd. A picture.