I am currently trying to select a centrifugal compressor for a wind tunnel project.

The requirement is that the flow velocity in the test section is Ma 0.1. The geometry of the wind tunnel has already been defined, so all the dimensions of the contraction nozzle, the test section, and the diffuser are known. With this requirement, a volumetric flow rate of around 3900 m3/h is determined.

The way I'm currently trying to approach this is through static pressure calculations at every point in the wind tunnel (using Bernoulli's equation with no losses and continuity A1v1 = A2v2).

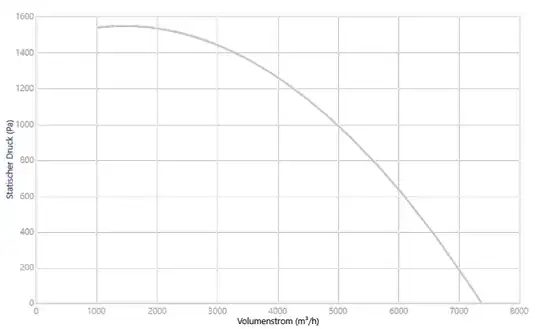

I came across this specific compressor curve:

The y-axis represents the static pressure and the x-axis represents the volume flow rate of the centrifugal compressor.

From the graph, a flow rate of 3900 m3/h gives about 1250 Pa of discharge static pressure. I'm assuming this means that the static pressure of air at the compressor inlet will increase by 1250 Pa at the outlet.

I have a couple of questions...

- How does one select a compressor using this curve?

- What does the static pressure at the diffuser outlet (also assumed the compressor inlet) and the compressor's outlet tell about the selection of the compressor? In other words, how does calculating them help in selecting the compressor?

- Does the compressor's pressure ratio actually matter in maintaining the velocity required at the test section or is it just the rpm? Like would using another compressor which has the same rpm but a lower pressure ratio affect the flow velocity at the test section?