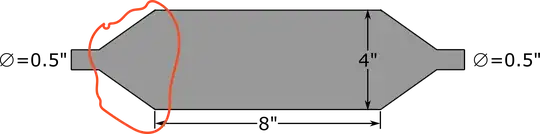

I have a small vessel with a rectangular cross-section which needs to be ventilated at a relatively slow rate, ~$3\ \tfrac{\text{L}}{\text{hr}}$. The connections to the vessel will be tubes with an approximately 0.5" diameter, but the cross-section of the vessel is 4" x 1". The diagram below gives a rough idea of the cross-section (viewed from above) with the height of the chamber being about 1". The part circled in orange is the topic of this question. The flow will be forced in from the left and will exit passively from the right (or vice versa).

How can I couple the 0.5" tube to the chamber such that the flow in the chamber is uniform across the entire cross-section for the entire length of the duct? In addition, how can I couple the two in the smallest amount of space possible?