I need a secure attachment mechanism for a robot arm tool changer that can snap one part into place by pushing it in and release it by pressing a button. This mechanism must reliably handle around 25 kg without any backlash, ensuring the part doesn't detach if the robot arm collides with an object or is accidentally bumped. It must be durable enough to withstand such impacts. I will turn this into a company in the future, so it needs to feel premium.

I am familiar with push-push latches, but they aren't suitable due to their vulnerability to accidental disengagement. My preference is for a mechanical solution without electronic components to maintain simplicity and reliability. Additionally, I want the mechanism to produce a distinct click sound when the part is securely locked in place, providing audible confirmation to the user.

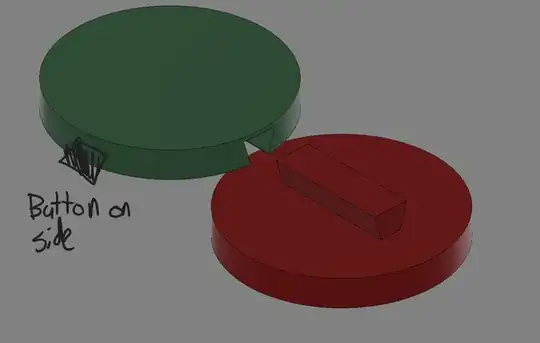

For the design, I need to connect two cylinders, each 59 mm in diameter and approximately 8 mm in height. The connection might benefit from a joint that aids in proper alignment. Here is a basic visual:

Example:

I found a great example of what I need to make here. At about 1:10 in the video, you can see the button to release it.

Some ideas:

I am thinking I could have a ball detent mechanism using this solenoid valve where the spring-loaded ball is housed in one part (green) and the corresponding indent is on the other part (red). I'm thinking of using two sets of these for enhanced security and to prevent accidental releases using two release buttons. However, I'm unsure how to design the button to effectively retract the spring.

While an electronically activated solenoid valve could serve this purpose, I am hesitant due to its added weight, cost, size, and complexity. An alternative might be a buckle mechanism, but my initial attempts with 3D-printed models proved insufficiently durable due to the necessary thin material. It was also difficult to achieve zero backlash.

I found this component from McMaster-Carr that could be of use, but it does not detail the internal mechanism.

Question:

Could you recommend an existing design or provide guidance on how to develop such a mechanism? An illustrative image would be highly beneficial.

Possible solution from @user721108:

User721108 suggested in the comments that a camera mount could be a viable option. I found this camera mount on Amazon, which appears to be a promising solution. The product listing does not provide a detailed view of the mechanism, so I will purchase it to disassemble and examine how it works. This seems like a great solution.