I have been making cylindrical concrete coasters and, for fun, have been seeing if my friend's can snap them. Every subsequent mix design I'll change the mix itself or the dimensions of the geometry to make the coaster stronger so that, hopefully, my friend's can't snap them.

I know that my mixes have high compressive strength and that they can't get much better in terms of maximising strength from that parameter (i.e. they are good mix designs), but I'm unsure about the flexural strength. I want to look at other ways of increasing the flexural strength other than changing the mix design (because iterating mix design testing can take a while and a lot of resources); logical and quick ways.

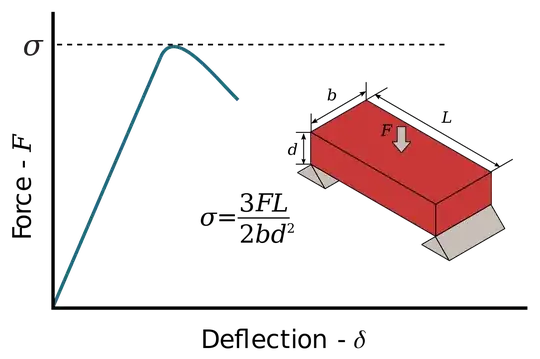

It makes sense to me that by increasing the thickness or height of the coaster that I will be increasing the flexural strength (i.e. because I'm imagining that it'd be easier to snap a thinner coaster than a thicker one and have experienced this), however, when I look at the formula I see that the reverse is true. The formula I've seen online (i.e from Wikipedia) is as below for a rectangular prism:

I believe this formula if it were to be adjusted for cylindrical samples would still be for the sample on its side being exposed to flexural stress rather than it sitting upright and being flexed (i.e. imagine breaking a thin cylindrical coaster). You can see from the formula that the thickness parameter is in the denominator, so increasing its value would decrease the theoretical flexural strength... this seems counterintuitive to me.

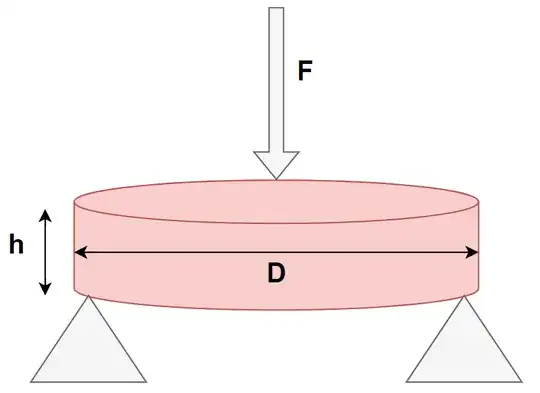

So, my question is, what would the correct formula be here? My latest coasters are 8 mm thick with a 90 mm diameter. How could I adjust the dimensions to make the flexural strength higher so that my friend can't snap them? He is quite strong but I'm determined to get him on this (without breaking his fingers!). For full clarity, I've added a labelled diagram below where h = height (or thickness or length), F = Force and d = diameter.