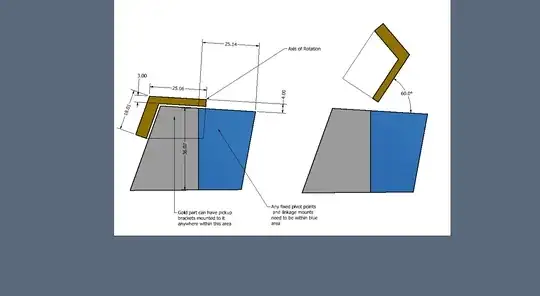

I had the same problem, and while Rotation around an axis outside of the mechanism pointed me in the right direction, it didn't provide a straightforward solution.

There are other ways to solve this, but I found that a double parallel four-bar linkage is easy to design and manufacture.

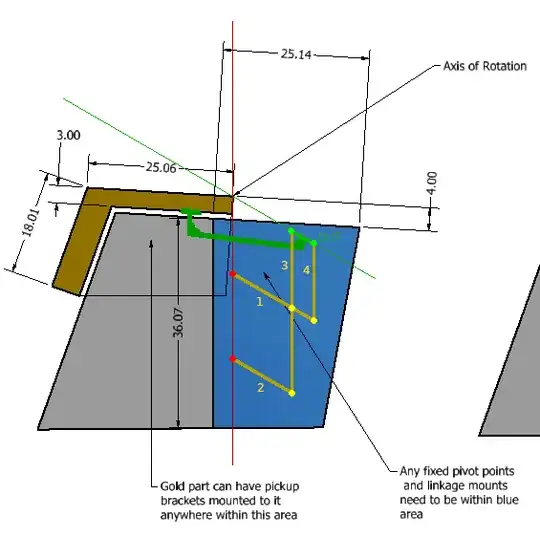

The design process is:

Draw two lines through the wanted rotation center and place two points on each:

The output bar (green) location. This should be positioned so that when rotated, it will remain in the desired area. Below I have positioned this at the top of the blue area, so it will move inwards when the mechanism opens.

The location of two fixed mounting points (red).

Note that the points can be placed anywhere along the lines, and the angle of the lines is free also. So you have great flexibility in the placement at this stage.

Add two link arms (yellow 1 and 2) from the fixed point that are parallel with the output bar.

Add two bars (yellow 3 and 4) that are parallel with the fixed mounting points and connect the link arms to the output bar.

Add a solid connection (dark green) between the output bar and the part to be moved. The connection can be any shape, as long as it is rigidly connected to the output bar.

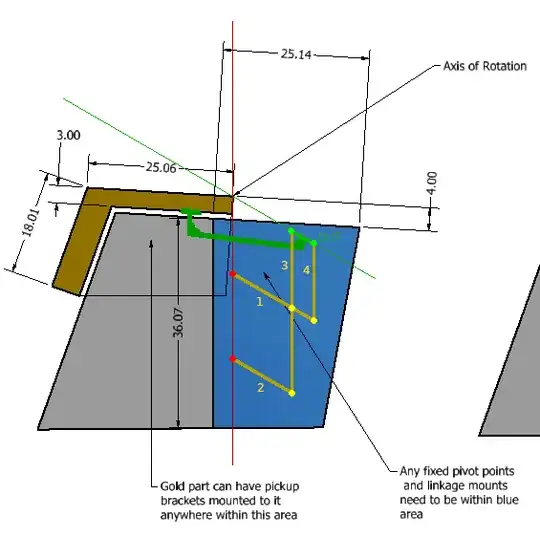

How it works:

The link arm 1 acts as a model for the rotation of the output bar. Its rotation point is offset along the red line from the desired pivot point.

The parallelogram formed by 1, 2 and 3 offsets one point from the link arm to the output bar. The arm 3 always remains parallel with the red line, and the distance to the output bar is same as the distance of the fixed points from the desired pivot point.

The second parallelogram formed by 1, 3 and 4 then keeps the output bar parallel with arm 1.

Thus the output bar has same angle as arm 1, and is offset upwards by the same distance as the upper fixed pivot point is from the desired pivot point. The output bar, and anything rigidly connected to it, will rotate around the target pivot.