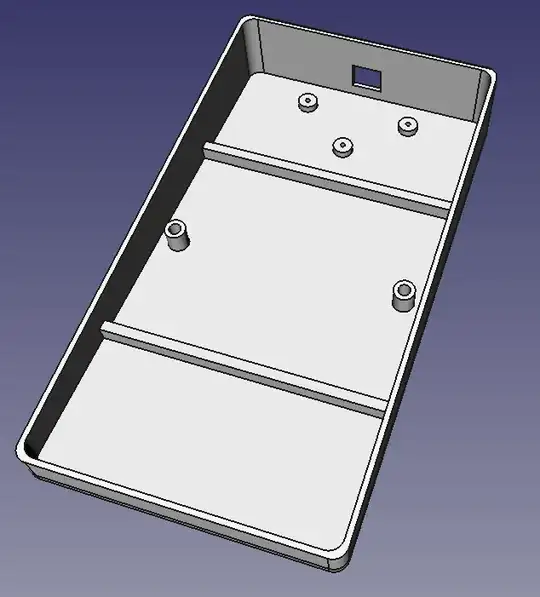

I'm drawing a box for a small electronic project:

It measures about 200x110 mm and I'm going to print it with PLA. The first attempt was without the ribs you can see on the bottom and it was very easy to twist the box.

Adding them gave a perception of greater robustness, but I wonder if there is a more suitable shape to further increase the stiffness.