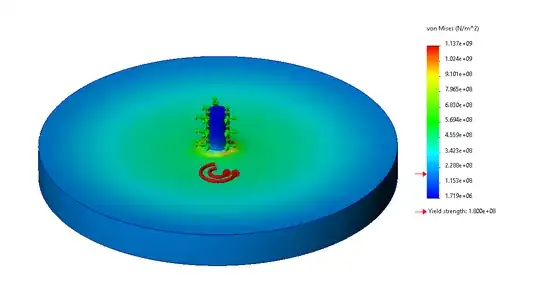

So I'm trying to run a centrifugal stress analysis on a flywheel in SolidWorks, but I'm unsure of how I should fix the model in a way where von Mises stresses are accounted for even at the center of the wheel. Most tutorials I've seen on YouTube recommend fixing the rod, but according to a flywheel's stress equation, the maximum stress occurs at the center of the wheel. As seen in the image, the simulation doesn't take into account the central stresses if I fix the rod.

In the model, the rod and the hub are part of the same piece. I'll add a hole at the top for a motor spindle and a bearing at the bottom, but first I'm trying to make sure the flywheel doesn't fail at high speeds.