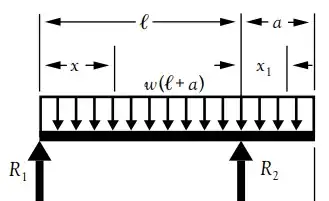

I am building a lightweight single axle trailer that needs to haul 600lbs cargo loaded evenly over the length of the trailer. Dimensions are 24.5 ft long including the tongue, by 3 ft 6 inches wide with an axle width of 5 ft 6 inches. Axle placement will be at roughly 18 feet from the tongue.

I plan on having a single center beam with 1 inch steel angle welded perpendicular at 3 ft increments to support the load. The steel angle will be welded to eachother with 1 inch angle in an "X" shape between them. No decking will be used.

The center beam I came up with is 2x2 inch steel box, 0.125 inch wall thickness, with a flange welded vertically across the bottom.

The flange is 0.200 inch thick flat steel and will be 1.5 inches tall at either end of the box tube, and 4 inches tall in the center. The steel box will be bowed to form a long shallow arch.

Is this a death trap, or will it be safe to use?