I have a design with two parts that would be produced via plastic injection (ABS injection molding). The two parts are small, around 10mm high each.

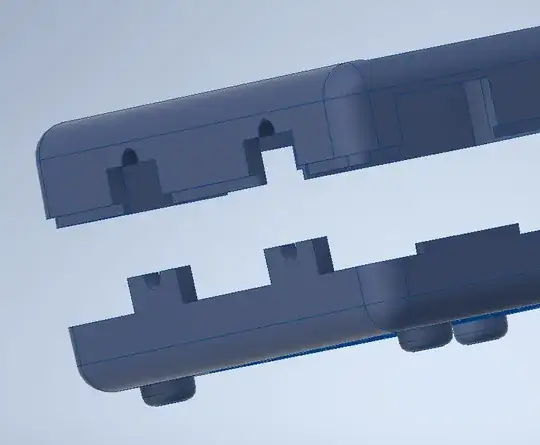

I have drafted both parts (inside and outside, 2°) but because of some buttons that can't be moved, the two pieces have a kind of "puzzle junction":

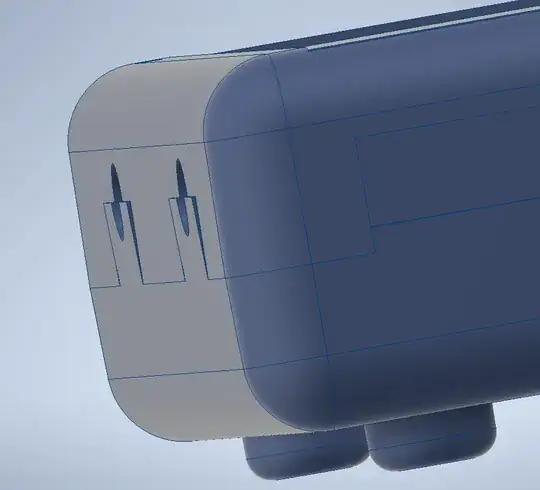

When the two parts are fitted together, the junction at the top of the "puzzle" is not well aligned because of the draft on different depths.

The delta around the buttons holes is very small: less than 0.15mm. I'm even not sure it would be noticeable especially as some buttons are going out.

how could I fix such problem?