Well, air has worse thermal conductivity than practically any solid, so chances are that a hole will decrease the heat transmission. There are however solids with thermal conductivity very close to that of air, so if that board was made (on purpose) from one of those... you won't see much improvement for your hassle.

And since you mentioned fiberglass while I typing this (doesn't quite look a common FR4 I have to say), then you might hope for halving of the conductivity given that Wikipedia give 0.024 Wm-1K-1 for air and 0.045 for fiberglass. I suspect with fiberglass though there can be a lot of variation between between various flavors because it's porous.

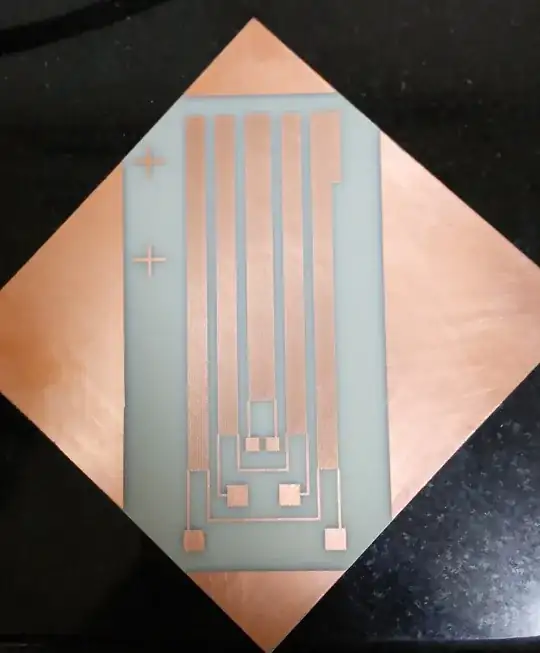

According to this presentation thermal conductivity of FR4 is a lot better at 0.25 W/m·K (5x) than that of pure fibeglass given by Wikipedia. (And actually that presentation agrees with https://en.wikipedia.org/wiki/FR-4#Properties but on the through-plane value). In-plane value is even greater there at 0.81 W/m·K to 1.059 W/m·K. I'm guessing the epoxy binder in FR4 contributes a lot to that. So on conducted heat alone you could hope for 10x (or even 40x) improvement in thermal isolation a with hole then. But then there's also radiated heat and depending how the board is oriented convection may contribute too. There are some examples/caculations on the web for radiative heat transfer between some simple geometries, e.g. here but I couldn't find something for yours.

There is software that can do this sort of complex thermal simulation, alas I don't know any free&good such, and it depends of course on having good material data. Actually, of the freebie stuff http://poweresim.com/newhelp/EN/thermal.jsp might help to some extent, but it seems it can only do some chunky blocks.

Actually, one thing you could do to estimate this is to position a termocouple in air at the same distance form the hot traces as the cold[er] traces are. And then measure what this registers. I suspect this would be a resonable approximation for what a hole could hope to achieve (ignoring he self-heating of the cold[er] traces).