I'm at the final steps of the job right before the pour but it only recently hit me that I might be on to collapsing my own house...

I bought an old house (europe) built in the 1960s using stone as foundation (no concrete) and solid brick. The first floor is half underground and the walls are lined with stone on the outside and brick on the inside. The wall thickness is about 50cm on the first floor and 25-ish cm on the second. I'm saying all this so you can get a basic picture that it is a pretty sturdy house.

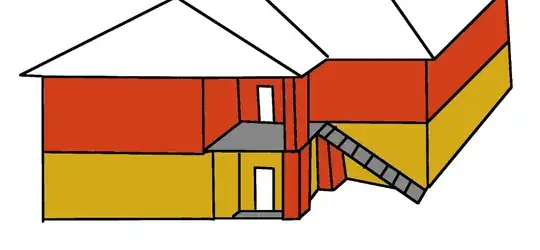

One of the few places where there is concrete used is on the porch (not sure if it's the correct term) where the entrances for each floor are. Here's a very bad drawing (added colors for easier differentiation), the grey parts are the stairs and the porch slab which are made from concrete:

So getting to the problem, the slab has visible cracks on it (which I suppose is normal) but there are patches on the underside where the cement plastering (they did as a finish) has fallen off and the rebar is visible and is in quite bad shape - rusted and easily breakable. The slab has visibly sagged in the middle by a good 3-4cm compared to the corners where it is supported but I cannot tell for sure if it wasn't poured this way or has sagged as it has deteriorated. It's dimensions are 2.7m by 2.8m by 5cm.

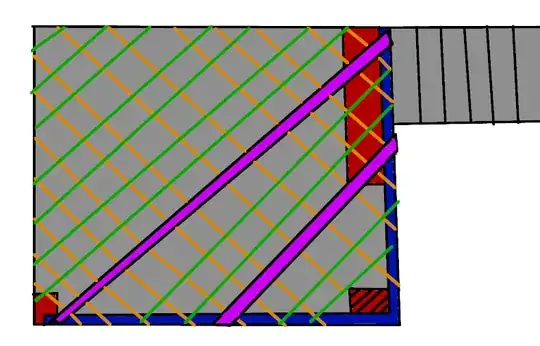

In order to strengthen it I decided to pour another slab on top of it and add metal bracing that is supported on the columns, here's a top view of what I have done:

In red are the brick columns, the one next to the stairs extends past them and the one on the bottom left is part of the wall of the first floor. The bottom right is the one that extends vertically to support the roof. In blue I have used 60x40x2 steel profile that is supported on all 3 columns and in purple I have 50x30x5 steel profile that is supported on the blue profile pretty much in the ends only because as I said the slab has sagged. In orange I have put 8mm rebar and in green 6mm rebar.

I thought it would turn out very strong, but in reality, the diagonal purple bar that goes through the center is 3.8m long and if I step on it it bends visibly and I'm only about 80kg. If I get other people to come step on it as well it doesn't bend very much more than with me on it only, which means it can take the load but it needs to bend first. Which in turn means, that if I pour concrete there it will fill the gap between the steel profile and the old slab (the sag space) thus any load that would otherwise cause the profile to bend will be taken by the old slab anyway. Which kind of negates the entire operation...

What I'm most concerned about is, as I calculate the required concrete to be about 0.5m3 which would result in roughly 1200 to 1500kg, what are the odds of the old slab breaking, taking along that outermost column and half of the roof along with it?