Rotating shafts are subject to deflections, even without applied (transverse) loads. To reduce excessive shaft deflection:

- Avoid operating speeds near the critical shaft speed, where the shaft vibrates at its natural frequencies.

- Ensure the shaft is concentric, where its center of mass rotates about its geometric center.

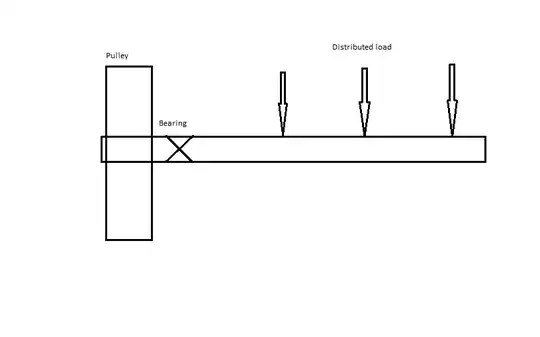

Assuming the shaft is concentric and does not operate at the critical shaft speed, deflections are caused by applied loads but depend on geometry and material. From your diagram, construct a Free Body Diagram and system of equations to solve for the reaction moment at the bearing(s).

$$\sum F: \qquad 0 = R_{bearing} - (F_{pulley}+F_{distrib})$$

$$\sum M_{@bearing}: \qquad 0 = M_{bearing} + F_{pulley}d_{pulley} - F_{distrib}d_{distrib}$$

Note that $F_{distrib}$ is the resultant force of the distributed load.

From the shear and bending moment diagrams, the bearing(s) must resist the reaction moment, $M_{bearing}$, required by static equilbrium (or the shaft is free to rotate about its transverse axes). Therefore:

Decrease force by reducing shaft speed

Select bearing(s) rated for the reaction moment, reaction forces, and operating speeds.

Modify bearing type or configuration:

A single ball bearing is not designed to resist bending moments. Instead, consider using wide needle bearings, double bearings, or (preferably) two separated bearings. Multiple bearings resolve the reaction moment to reaction forces applied at a distance ($M = Fd$), where greater distance between bearings reduce $R_{bearing}$. These design options are illustrated below.

From the deflection equations, the following design parameters further reduce shaft deflections (note that these parameters are only applicable if the bearing(s) resist the bending moments):

- Increase shaft diameter

- Select a stiffer material

Used in combination, these parameters are used to design shafts according to design requirements (geometry, material, loads, allowable deflections).