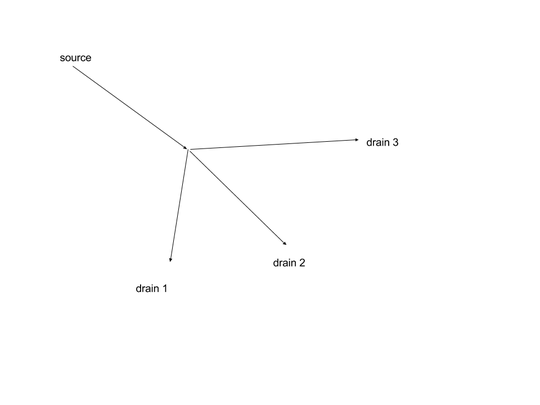

This is essentially explaining how to solve parallel flow problems using the fundamentals on fluid dynamics - let me know if you need additional information.

Let's assign some variables. Let's let:

- Q1, Q2, Q3, and Q be the flow rates in each of the pipes (Q is the overall flow). Note Q = V * A, where V1, V2, and V3 are the fluid velocities. A1, A2, A3 being the channel area used.

- Z1, Z2, Z3 and Z are the heights above sea level of each of the outlets (Z is the cross point).

- Let's assume you are working with manning formula - in this case, convert the Zs into different slopes - S1, S2, and S3. If your drains slope changes along the way, you can model it using an average slope, or you can model using several pieces of pipe in parallel. The average slope is easier, and generally accurate.

- While X, Y, and Z are nice - let's use L1, L2, and L3 for the lengths of each pipe.

- Finally, we need the energy in each of these points. Note that power is used because for a steady state assumption, the energy would be infinite. So, Power = Flow Rate * Pressure (Check out the units!). Here, we use P1, P2, P3 and P for the powers at each ending - P Being the power at the cross point. For the power consumed by friction along the length, let's use Pf1, Pf2, and Pf3.

- Rho is the density of the fluid. D is hydraulic diameter (D1, D2, D3 for consistency).

Now the total power at the cross point must be the total power - expended via friction along the pipes or delivered at the outlet. That's just conservation of energy. For a bunch of reasons though, power is not in units of Watts like it should be for fluid dynamics. It's in units of length - the height of a reservoir of energy. It's called head. I'm explaining this in terms of power, and it's valid - but it's not historically accurate.

The power expended by the pipes:

Pf1 = rho*Q1*f*(L1/D1)*(Q1/A1)^2/2

f is of course the Darcy Friction Factor. Of course, to solve for f, you need to obtain Q. But Q is unknown! So, we guess at an f, check the problem via iteration, solve for Q, then check that the guess for f was valid. If we're close, move on - otherwise guess at a new f and keep going.

With this friction formula in mind, then the power consumed by each of the channels is:

P1 = (Z-Z1) * rho * Q1 + Q1^3*rho/(2*g*A1) + Pf1

With this in mind, at last we have the equations needed to solve this problem:

Q1 + Q2 + Q3 = Q

P1 + P2 + P3 = P

Q1 = A1*(k/n)*D1^(2/3)S1^(1/2)

Q2 = A2(k/n)*D2^(2/3)S2^(1/2)

Q3 = A3(k/n)*D3^(2/3)*S3^(1/2)

With this, we have five equations and 3 unknowns - the various Q1, Q2, and Q3. The simplest solution is to iterate through and find 3 Qs to solve all 5 equations, disregarding the most empirical assumptions first (in this case, I'd disregard the f's - followed by the Manning equations. Energy and Mass conservation is top priority).