I'm developing a code to simulate thermal performance of automotive radiators.

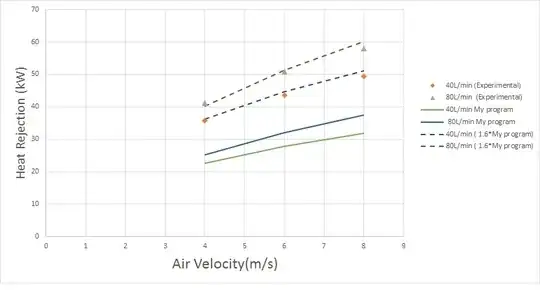

My results are 40% under-predicted. But when I multiply them to 1.6, they match completely.

This is the graph that compares the results of program and experimental work.

It should be noted, this number (1.6) differs when we use the other data sets.

Procedure of the program is as following :

given air velocity, coolant flow rate, inlet air and coolant temperatures.

assume outlet air and water temperatures (it should be a logical assumption).

calculate air and fluid properties (using interpolation in existing tables based on mean temperatures)

calculate heat transfer coefficient of water according to flow regime (using Petukhov or Gnielinski equations)

calculate Colburn j factor (using Chang and Wang empirical correlation)

calculate the total thermal resistance between air and coolant.

calculate NTU and effectiveness

Calculate heat rejection

Calculate outlet temps and compare them with assumed temps. If it doesn't meet the specified error, go to step 3 and repeat calculations.

clc;clear all

% _____Jung Experiment_______

% Air Velocity m/s

Va=4;

water_Flowrate=2e-3/3;% m3/s (40 L/min)

% Top tank and inlet air temperatures (deg C)

twih=85; t_ambient=25;

% Specifying the j-factor correlation (Chang & Wang)

cor='CW';

% Entering the Radiator characteristics

cas='C:\Users\Solid\Desktop\jung.xlsx';

% ___ Calculation ___

ITD=twih- t_ambient;

% Export Geometrical details from jung.xlsx file and calculate the needed

% Areas like AT(total heat transfer area etc).

[R,L,Afrt,Afrf,Ac,Afront,sigma,Af,Aw,AT...

Lp,Fp, Fl, Ll, alpha, Fd, Tp, deltaf, Nlb,Td,LH,af,Dh,NT,kf...

RH,RW,RD,N,Nct,Np,Nf,Yl,Dm,D_major,W,tt]=Area_Calc(cas);

% Radiator tubes are flat. So we need hydraulic diameter(dw).

[dw,A_cross,Perimeter]=hydro2(Dm,L);

% ___ Pre_Procssing ___

t_top_tank=twih;

twi= t_top_tank;

tai = t_ambient;

% defining an error;

error=.01;

% Assuming outlet temperatures of water(Two) and Air(Tao) logically.

Tao=50; Two=75;

Y=1;

% defining a counter;

ll=0;

while Y

Q=0;

ll=ll+1;

% At the end of the loop, calculated temperatures will be compared

% with the tepms of the past iteration.So we save the tepms of the

% past iteration here.

Two1=Two; Tao1=Tao;

% Calculating the properties like viscosity(uw(coolant),ua(air)),Prandtel

% Number (Pra(air) ,Prw(coolant)) etc.

[ uw,ua,rhow,rhoa,cw,ca,kw,ka,Prw,Pra,tam ]=...

phyprop2(twi ,tai,Two,Tao);

% Air side Reynolds number. ReLp is the reynolds number based on

% Louver pitch.

ReLp=rhoa*Va*Lp*1e-3/(ua);

ReDh=rhoa*Va*Dh*1e-3/(ua);

% Air mass flowrate

mair=Ac*rhoa*Va;

% --- Coolant side Reynolds number and mass flowrate ---

[Rew,mwater]=hydro(dw,A_cross,water_Flowrate,rhow,uw,...

NT,'I');

% coolant heat transfer coff.

[hw]=hc2(Yl,dw,Rew,kw,Prw,1);

% Air heat transfer coff. and friction factor

% (friction factor(f) will be calculated but won't used in this program )

[ha,jcor,f]=ha2...

(Lp,Fp,Fl, Ll, alpha,Fd, Tp, deltaf, Nlb,Td,LH,Dh,ua,rhoa,ca,Pra,...

Va,cor,ReLp,ReDh,Dm,tt);

% ----------- UA , NTU--------

l=Fl*1e-3/2;

M=sqrt(2*ha/(kf*deltaf*1e-3));

% fin and Surface efficiency

nf=tanh(M*l)/(M*l);

no=1-Af*(1-nf)/(AT); Q=0;

% ----------Capacity Rate-----------

Ca=mair*ca; Cw=mwater*cw;

if min(Ca,Cw)==Ca

Cmin=Ca;

Cmax=Cw;

Q=1;

else

Cmin=Cw;

Cmax=Ca;

end

Cs=Cmin/Cmax;

% Calculation of overall heat transfer coefficient using thermal

% resistances between air and water(fouling and wall resistances are

% negligible)

UA=(( 1/(hw*Aw)+1/(no*ha*AT) ) )^-1;

NTU=UA/Cmin;

% ------------- E - NTU (calculation of effectiveness _epe_ using existed

% correlations) -----------------

epe=eps1(Q,N,Cs,NTU,Cmin,Ca);

% Air and water outlet temps

tao=tai+epe*Cmin*(twi-tai)/Ca;

two=twi-epe*Cmin*(twi-tai)/Cw;

Tao=tao;

Two=two;

% do these temps meet the errors ?

Y=abs(Tao-Tao1)/Tao>error2 ||...

abs(Two-Two1)/Two>error2;

end

% Radiator Heat Rejection

q=epe*Cmin*ITD;

disp(q)

What's wrong?