Steel or aluminum can be made equally strong. Generally aluminum can more easily be designed to have a higher strength to weight ratio because it has the a larger area moment of inertia for a given mass.

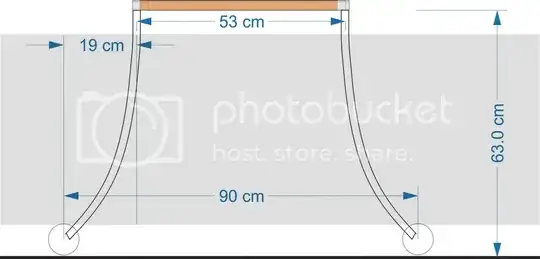

Like Olin Lanthrop mentioned in the comments, the weakest link will be your connection between the table top and the legs. You can't count on the friction of the surface to hold the legs from moving outward(even in directions the wheels may not roll). If you add cross bracing (steel cables, aluminum rod, etc) your design will be lighter overall. Even a single 1/8" rod between wheels on the bottom would increase the strength considerably.

The primary failure modes that will need to be designed for are:

- Buckling of the legs, hard to calculate that shape without FEA. If design fails in testing; increase wall thickness or add cross bracing (think triangles).

- Joint failure between the legs and the table top. Make sure that this joint exceeds the strength of the legs and table top; especially if you go without cross bracing.

- Buckling of the table top. Probably the easiest to calculate. Make sure to include the moments added by the legs that are cantilevered.

- Deflection beyond limits. You may find that even though a given design is strong enough it may not hold the tolerances you wish. Under load this table will bow in the middle. The permissible deflection for a given load may require thicker members or more structure.