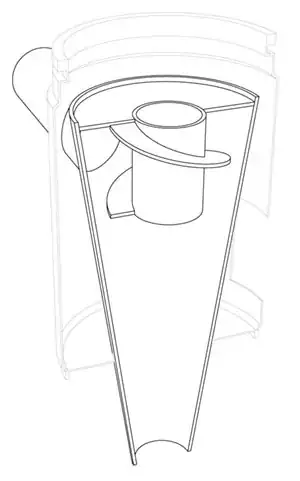

I'm making a dust extractor for a desktop CNC milling machine. My design process was very crude: I looked at some DIY dust-separating cyclones, and it seemed like they just work without any advanced calculations, so I visually copied some of those designs at a smaller scale, sat a large PC cooling fan over the top, and put the whole thing in a coffee can:

My reasoning was that (1) the 18W fan blows out a lot of air, (2) the only place for that air to come from is through the hole at the top of the cone, and (3) the only way air can get into the sealed cone / dust receptacle (the bottom can) is through the tube at the side. So, it would have to suck a reasonable amount of air through that red pipe.

It does work to some extent (video), but not as well as I hoped. You can see that it barely picks up sawdust through a 1-inch hose, and ideally I'd like it to draw in dust at a range of 20-50mm or so-- I can't position the inlet any closer than that to the point where the dust is created. Plus, I'd like to fit a dust filter over the exhaust hole, which will reduce the air flow even more.

My question is basically "how can I make it suck harder?". But more specifically, how do I start to analyse what's happening, and what determines the amount of air pulled in?

Most Google references are either way over my head, or talk very specifically about pumps in volute casings; obviously I removed the volute casing from my fan in order to fit it in the enclosure. If I understand correctly, the point of the volute is to make the fast narrow stream exiting the fan into a slower, wider stream at higher pressure (why?), and I guess that something similar happens in my can:

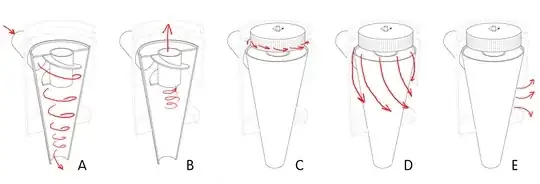

A) incoming air spirals down; dust is thrown out and drops through bottom of cone

B) clean air spirals up through fan inlet

C) fast air exits fan circumference

D) ...and expands into volume below, losing speed and increasing pressure

E) higher-pressure air blown out into atmosphere

Stage C/D is the part I'm most uncertain about. The rest of the design comes from recipes, but I've changed the way air exits the fan and would like to understand how this might affect things.

Edit 4 Feb 2016:

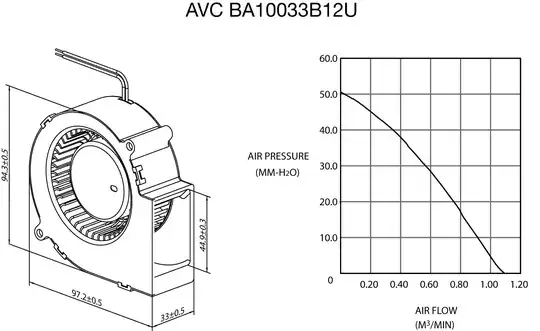

Per @ericnutsch's suggestion, I made rough measurements of the air flowing into stages A and C, and got a figure of about 0.009 m3min-1 at both points. I also found the manufacturer's data for the fan, which suggests I should be able to do better-- the stated max is 1.09 m3min-1. For comparison, my crappy handheld vacuum scores around 0.024 m3min-1. I've ordered a pressure sensor to investigate further...