I am trying to model a prototype resembling a section of vein channels. I am wondering if there are some basic rules for such fluid channels, for instance when a vein splits in two capillaries, is there some quantity conserved (area of the section or else)? I observed that with my current design (which is done by hand just imitating pictures I saw) the fluid I pump in tends to flow very fast in some channels and very slow in others. I'd want some sort of common front to advance. I am a mathematician and have ZERO education on fluid dynamics or else :) any help is much appreciated!

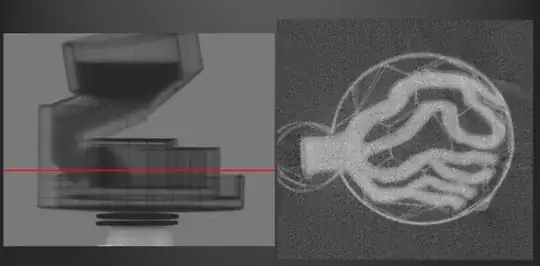

EDIT: I saw the comment answer and I apologise because I am not sure I will be able to formulate my question in a decent way for engineers :). I am printing my model in rigid plastic and the application is scanning its section in the X-ray CT lab. Here's a couple of pics that I hope will clarify my position:

The idea is to have a viscous fluid (honey+iodine) put in the top "funnel" and start measuring in the CT lab, observing it flowing into the bottom channels. Observe that the channels have a rectangular section.