In intuitive terms I have found the following explanation to be useful.

For the sake of argument lets say that our system is filling a bucket with a hole in it water from a tap. We measure the depth of water in the bucket and control the flow rate of water via a tap. We want to fill the bucket as quickly as possible but don't want it to overflow.

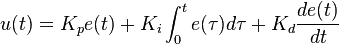

The proportional element is a linear measure, in this case the height of the water in the bucket this is a useful measure of how full the buck is at a given time but it tells us nothing about how quickly it is filling so by the time we notice it is full it may be too late to turn off the tap or if we fill it too slowly water will leak through the hole faster than it fills and it never quite gets full.

On paper this sound s like it should be enough on it's own and in some cases it is, however it break down when the system itself is inherently unstable (like an inverted pendulum or a fighter jet) and the lag between measuring the error and the input taking effect is slow compared to the rate at which external noise induced perturbations.

The derivative element is the rate of change of the water level. This is especially useful when we want to to fill the bucket as quickly as possible eg we might open the tap as far as it will go at the start to fill it quickly but close it off a bit once the level gets near the top so we can be a bit more precise and not over fill it.

The integral element is the total volume of water added the bucket. If the bucket has straight sides this doesn't matter much as it fills at a rate proportional to the flow of water BUT if the bucket has tapered or curved sides then the volume of water in it starts to have an effect to the rate at which the water level changes. More generally because this is an integral it accumulates over time so applies a greater response if the P and D elements aren't correcting enough eg by maintaining the bucket at half full.

Another way to look at this is that the integral is a measure of the cumulative error over time and is effectively a check on how effective the control strategy is at achieving the intended result and is able to modify the input depending on how the system really behaves over a period of time.

So in summary :

the P (proportional) element is proportional to the variable that you want to control (like a simple thermostat)

the D (derivative) element is proportional to the rate of change of that variable

the (integral) element is perhaps the most difficult to understand but relates to the quantity that your P parameter is measuring typically this will be a cumulative quantity like volume, mass, charge, energy etc.