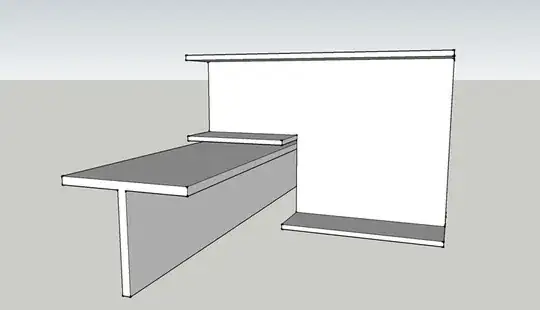

I need to have some beams fabricated with copes on the ends. They will be set on top of existing steel trusses, and used to replace undersized purlins to shore up existing rafters (hence the need for the copes).

My structural engineer specified 4" long copes. There is a cope at each end. The distance between the edge of the flanges on the steel trusses is 186".

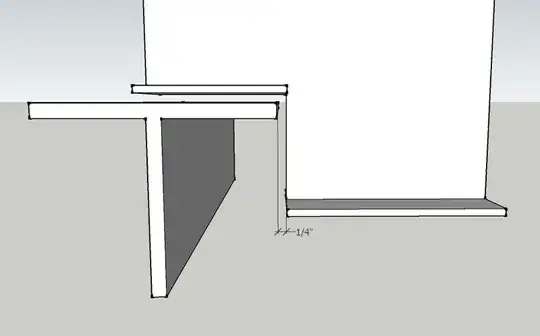

The question is a matter of practicality. If I have the fabricator make the coped length of the beam exactly 186", I feel like I may have a difficult time getting the beams in place. So I'd like to have a little tolerance to give me room to slide the beam above one truss and then pivot it into place above the other.

How much tolerance should I allow for to make this easy on myself, the installer of the beam, without diminishing the integrity of the design? In the CAD drawing below, I have just arbitrarily chose to show that the coped end-to-coped end distance should give me 1/4" of play on each end of the beam.

I don't want to overthink this, but these suckers are heavy and installing them is going to be fun enough without having to fight tolerance problems.

Is there a tolerance rule of thumb for this situation? What tolerance would you use?