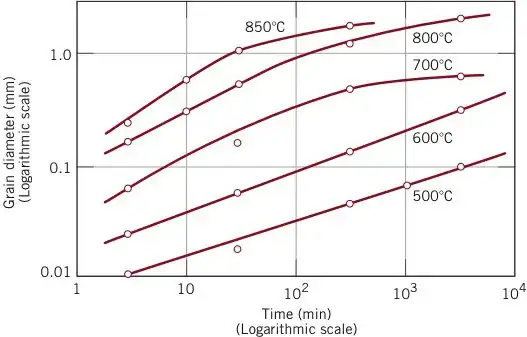

An uncold-worked brass specimen of average grain size 0.009 mm is heated to 600 degrees Celsius for 1000s, what is the average grain size based on this graph?

How to tackle this problem? I don't know if I am using the graph correctly. My approach was:

1000s is 16.67 min, $\log(16.67) = 1.22$

So $\frac{22}{100}$ between 10 and 102. Which is about 0.67 cm to the right of 10 on x-axis.

Now lets estimate this corresponds to 10-1.333 on the y-axis of the 600 degrees celcius graph line. So 0.046 mm.

But this does not seem correct, because I did not incorporate the 0.009 mm starting position. Which corresponds to heat treatment time of about 1 min at 600 degrees so should I add 1 min to the 1000s? And thus look look at the point on the graph at 17,76 min?

The answer in book seems way off, they talk about average grain size 0.2 mm. To me that seems like they looked at the graph of 700 degrees Celsius.