Conductive paint by conventional technique using gum and graphite powder does not stick to the PDMS surface and comes off once the paint dries. How else can I make a conductive connection over the PDMS surface so that it can stick to it nicely?

1 Answers

As you asked both, "How to make a conductive paint over PDMS?", and, "How else can I make a conductive connection over the PDMS surface so that it can stick to it nicely?", I will answer the latter question as your 'conductive paint' has been problematic for this application and there are already well established methods for conductive coatings for this particular material.

One option is sputtering. Sputtering is a technique that is widely available and is a fairly inexpensive process for coating materials such as PDMS. Sputtered films also have an advantage over other coatings (such as your gum paint), in that these films typically have strong adhesion to the surface being coated and it is a non-destructive technique (e.g. it works well enough to be used in electron microscopy).

Au, along with a host of other metals, are available for coatings, and they can be laid down in various thicknesses at rates from 10's to 1000's of nanometers per minute. In addition, this has been done many times before with this material and can give you the conductive surface you are looking for.

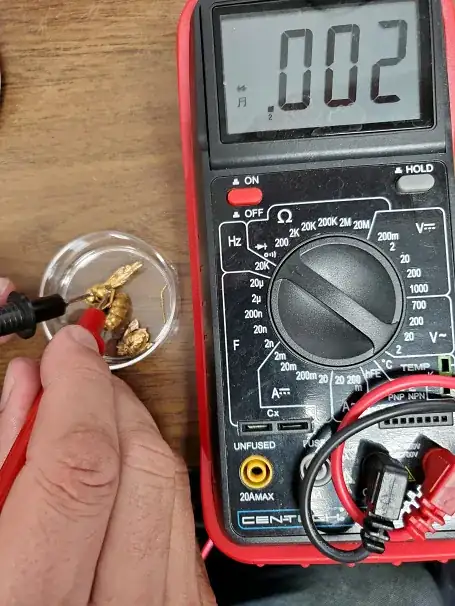

Here is a wasp we coated awhile back for the microscopy labs:

The Au has a resistivity of a less than 2 ohms across the wasp, and could be sharply reduced with a thicker coating and a more uniform sample surface.

Considering you have been painting the PDMS surface, I am inclined to assume minimal damage to the micro-structures is not an issue as is sometimes caused by this process.

A second, and potentially easier option, is to simply use an Au, Ag or other conductive foil, although it is difficult to say if this is a good direction for your project as we have few details.

Hope this helps!

- 726

- 5

- 16