Reading your question, my understanding is that you trust your engineer to have done at least a reasonable job designing the structure. You aren't worried the structure might collapse, that the engineer might have forgotten a load case or that they might have chosen inefficient cross-sections types (i.e, they didn't use rectangular columns). I understand you are only concerned with knowing whether the structure, as is, is inefficient.

There are therefore two ways the structure might be inefficient: the structural plan is poorly designed and/or the cross-sections adopted for each element are excessive and therefore inefficient.

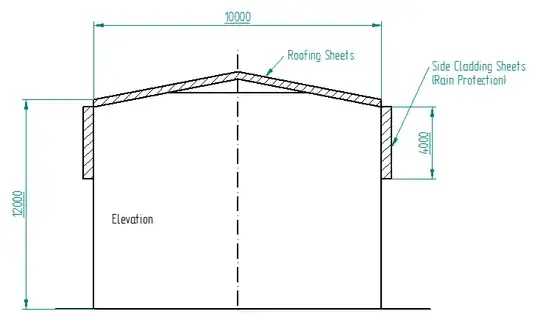

A 10-meter span sounds pretty reasonable at a glance, as does the elevation presented, so I don't think we need to concern ourselves with the "poorly designed plan" scenario. This leaves us only to check the cross-sections.

Steel elements are often designed according to a "utilization rate". This is a value which goes from 0.0 to 1.0, where 0.0 means the element is not under any loading under any circumstance and 1.0 means that under some load combination the element is having to resist forces exactly equal to its design strength. Obviously, a utilization rate above 1.0 means the element risks failure (though I believe some codes allow rates slightly above 1.0 in some situations).

An easy way to check your engineer's work is to look at their design calculations for each element and check the utilization rates (they may also be expressed in terms of "this element suffers $X$ and can resist $Y$, $X < Y \therefore \text{OK!}$", in which case the rate is equal to $\frac{X}{Y}$). If they are all close to 1.0, then the structure isn't overly conservative.

What exactly counts as "close to 1.0" is tricky to define. Steel elements have discrete cross-sections; you can choose between section A or B. In some cases, it may be that section A is insufficient (utilization rate above 1.0), while section B is quite a bit bigger, in which case the engineer will have no choice but to select B, even though its rate isn't very efficient. Therefore, unless you're an engineer yourself and can actually redo your engineer's math testing other possible cross-sections, I suggest you be generous in what you consider "close to 1.0".

Obviously, if all of the elements are requiring your generosity, then that probably means that a slight modification to the plan would improve significantly your global design. For instance, a 10-meter span between the supporting frames shown in the elevation may mean that the columns fell under the "section A or B" scenario described above. In such a case, it may be that reducing that span just a bit allows you to improve significantly the efficiency of your columns.

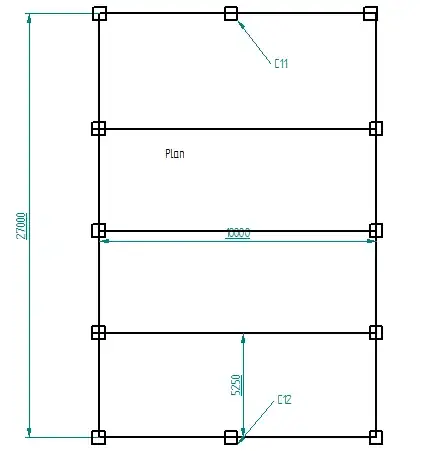

That being said, if you have a continuous element, you might have different rates for different parts of the element. For example, a continuous beam with multiple spans of different lengths might have a rate for each span. The engineer must then decide between making a uniform beam which is equal for all spans (and which will therefore be a bit inefficient in the smaller spans) or use different cross-sections for each span. The latter choice may be more material-efficient (since you optimize the cross-section for each span), but may very well actually be more expensive due to the increased complexity of the joints. The decision between these two choices is not trivial, so I honestly suggest accepting your engineer's better judgement (if you have any confidence in it). The same applies to columns: those at the corners will usually have to resist lower forces than the central ones, so the engineer must decide between adopting one cross section for all columns or different sections for each one. In this case, it is very common to adopt one section for all.

If you are truly concerned about the design, another option would be to hire a second engineer to do a quick "quality control" check of your project.