I find such a column hard to justify.

As mentioned by @grfrazee and @ChrisJohns, what you are calling a "thunk" is usually called a bearing plate, and these are responsible for transmitting the force from the superstructure (beams) to the mesostructure (columns).

As mentioned by @ChrisJohns, these bearing plates may well be bolted, in which case a minimal distance to the edge of the column is necessary. That being said, these distances are usually quite small, and at a glance it seems to me that the smaller column diameter would be sufficient to satisfy that distance.

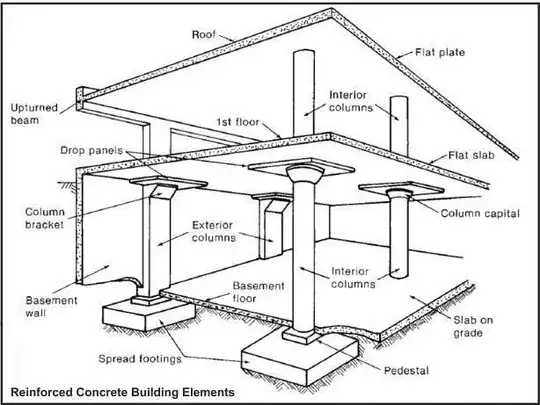

@grfrazee defines the flaring as a capital, but I'm not sure that's what we're seeing here. Capitals are mostly used when a column supports a slab directly (as opposed to supporting a beam which supports a slab). Their purpose is to increase the contact area and therefore decrease the punching force on the slab. Given that these columns are not supporting slabs (and even if they were, the bearing plate forces a concentration of punching force regardless), I don't think the flaring of the column is meant to be a capital.

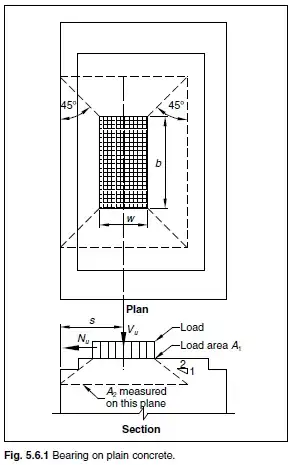

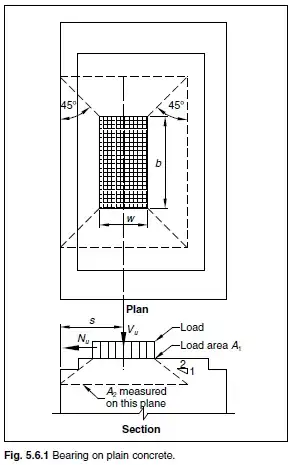

@grfrazee's image (repeated below) also raises another problem with this flared column head. By increasing the size of the column, they have increased the size of area $A_2$ in the figure below. This increases the bearing strength at the head, but if this compression were the ruling factor, you'd have the same problem away from the "capital", once the section is reduced.

The ratio $\dfrac{A_1}{A_2}$ (as opposed to $\dfrac{A_2}{A_1}$ when calculating bearing strength) is used when calculating the splitting forces at the head of the column, and the smaller this ratio (or, the larger $A_2$ is in proportion to $A_1$), the greater the splitting forces.

So honestly, I can't really see a valid motivation behind using such a column.